The conveyor belt is a friction-driven machine that can continuously transport materials over long distances. It is generally used in various production lines such as crushing, sand making, and mineral processing.

The belt conveyor is widely used in factories because of its simple structure, automated operation, strong transportation capacity, smooth operation, and automatic unloading.

It solves the transportation problems of long transportation distance and high labor cost.

Get the Latest PriceThe belt conveyor has the capability to transport a variety of materials, with densities spanning from 0.5 tons per cubic meter to 2.5 tons per cubic meter.

These materials include coal, ores, rocks, sand, construction debris, slag, glass, and more.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying capacity (t/h) |

||

| 400 | ≤10 3 |

12-15 3-4 |

15-30 4-7.5 |

1.25-2.0 | 30-60 |

| 500 | ≤10 3 |

12-15 4-5.5 |

15-30 5.5-7.5 |

1.25-2.0 | 40-80 |

| 650 | ≤10 4 |

12-15 7.5 |

15-30 7.5-11 |

1.25-2.0 | 80-120 |

| 800 | ≤10 4 |

12-15 7.5 |

15-30 7.5-15 |

1.25-2.0 | 120-200 |

| 1000 | ≤10 5.5 |

10-20 7.5-11 |

20-40 11-22 |

1.25-2.0 | 200-320 |

| 1200 | ≤10 7.5 |

10-20 7.5-15 |

20-40 15-30 |

1.25-2.0 | 290-480 |

| 1400 | ≤10 11 |

10-20 15-22 |

20-40 22-45 |

1.25-2.0 | 400-680 |

| 1600 | ≤10 15 |

10-20 22-30 |

20-50 30-75 |

1.25-2.0 | 600-1080 |

| 1800 | ≤10 18.5 |

10-20 30-45 |

20-50 45-110 |

1.0-2.0 | 800-1500 |

| 2000 | ≤10 22 |

10-20 45-55 |

20-50 55-132 |

1.0-2.0 | 1000-2000 |

| 2400 | ≤10 30 |

10-20 55-75 |

20-50 75-185 |

1.0-2.0 | 1500-3000 |

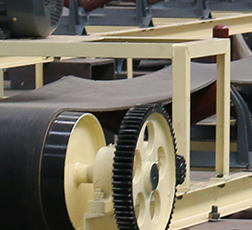

The belt conveyor is supported by upper and lower load-bearing rollers and bypasses the head roller and tail roller to form a closed loop.

It uses the friction between the driving roller and the conveyor belt to transmit power and realize material transportation.

Our belt conveyors are made of two-layer high-quality materials, which include rubber, PVC, polyurethane, neoprene, nylon, polyester, and leather.

We provide versatile movement options, allowing movement in both directions and horizontal, diagonal up, and diagonal down transport of materials.

The conveyor belt, with running wheels, offers flexible movement and quick disassembly. Enclosed versions cut dust pollution, boost efficiency, and enable automatic material unloading.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.