The vibrating feeder is widely used in crushing and screening combination equipment in steel plants, coal plants, sand and gravel plants, cement, aggregates, glass, construction waste recycling, building materials, and other industries to provide uniform and continuous feeding.

A vibrating feeder is a feeding equipment that utilizes a controlled vibration force system and gravity to provide uniform, continuous feeding and reduce the risk of material clogging.

Get the Latest PriceThe vibrating feeder is suitable for processing bulk and granular materials, such as coal, granite, basalt, limestone, quartz stone, gypsum, talc, barite, river pebbles, iron ore, construction waste, slag, etc.

| Model | Sieve specification(L×W) |

Sieve layer |

Mesh size |

Feeding size |

Processing capacity | Motor power |

Total weight | Vibrating frequency | Double amplitude | Sieve obliquity |

Dimensions (L×W×H) |

| (mm) | (mm) | (mm) | (t/h) | (kw) | (kg) | (Hz) | (mm) | (℃) | (mm) | ||

| ZSG1237 | 3700×1200 | 1 | 4-50 | ≤200 | 10-100 | 5.5×2 | 2250 | 16 | 6-8 | 15 | 3800×2050×1920 |

| 2ZSG1237 | 3700×1200 | 2 | 4-50 | ≤200 | 10-100 | 5.5×2 | 3345 | 16 | 6-8 | 15 | 3800×2050×2200 |

| ZSG1443 | 4300×1400 | 1 | 4-50 | ≤200 | 10-150 | 5.5×2 | 4100 | 16 | 6-8 | 15 | 4500×3040×2500 |

| 2ZSG1443 | 4300×1400 | 2 | 4-50 | ≤200 | 10-150 | 5.5×2 | 4900 | 16 | 6-8 | 15 | 4500×3040×2700 |

| 3ZSG1443 | 4300×1400 | 3 | 4-50 | ≤200 | 10-150 | 5.5×2 | 5870 | 16 | 6-8 | 15 | 4500×3040×2820 |

| 2ZSG1548 | 4800×1500 | 2 | 5-50 | ≤200 | 15-200 | 7.5×2 | 5836 | 16 | 8-10 | 15 | 4800×3140×2814 |

| 3ZSG1548 | 4800×1500 | 3 | 5-50 | ≤200 | 15-200 | 7.5×2 | 6900 | 16 | 8-10 | 15 | 4799×3140×3014 |

| 2ZSG1848 | 4800×1800 | 2 | 5-50 | ≤300 | 50-500 | 7.5×2 | 6489 | 16 | 8-10 | 15 | 4799×3440×2814 |

| 3ZSG1848 | 4800×1800 | 3 | 5-50 | ≤300 | 50-500 | 7.5×2 | 7750 | 16 | 8-10 | 15 | 4799×3440×3014 |

| 4ZSG1848 | 4800×1800 | 4 | 5-50 | ≤200 | 50-500 | 11×2 | 8300 | 16 | 8-10 | 15 | 4799×3440×3503 |

| 2ZSG1860 | 6000×1800 | 2 | 5-150 | ≤300 | 80-600 | 11×2 | 9950 | 16 | 8-10 | 15 | 6000×3440×3326 |

The motor causes the eccentric block of the vibrator to rotate at high speed through the V-belt, stimulating the screen box to produce a circular motion of a certain amplitude.

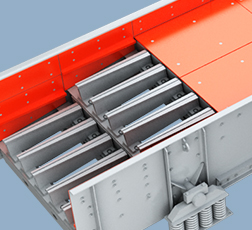

The materials on the screen produce continuous throwing motion on the inclined screen surface, allowing particles smaller than the screen hole to pass through the screen, thereby achieving classification.

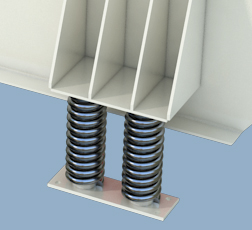

The spring support adopts a pin structure to facilitate the adjustment of the inclination angle of the feed box (0–20°) to meet the feeding and screening requirements of different materials. Adjusting the excitation force can make the ore feeding amount continuous and uniform.

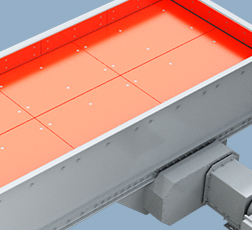

A rectangular section is used as the feed end support, and the outside of the side plate is reinforced with angle steel, giving the feeder a solid load-bearing structure. The rubber spring parallel tensioning structure and super strong vibrator make it stronger in impact resistance and smooth operation.

The screen bars made of ZGMn13-4 have stronger bearing capacity. The comb shape of the sieve holes and the large drop of the sieve bars can be used for preliminary screening of materials to prevent clogging.

Using resonance, it has low power consumption, low noise, low failure rate, small wear on the trough, and is closed to prevent dust pollution and is economical to invest.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.