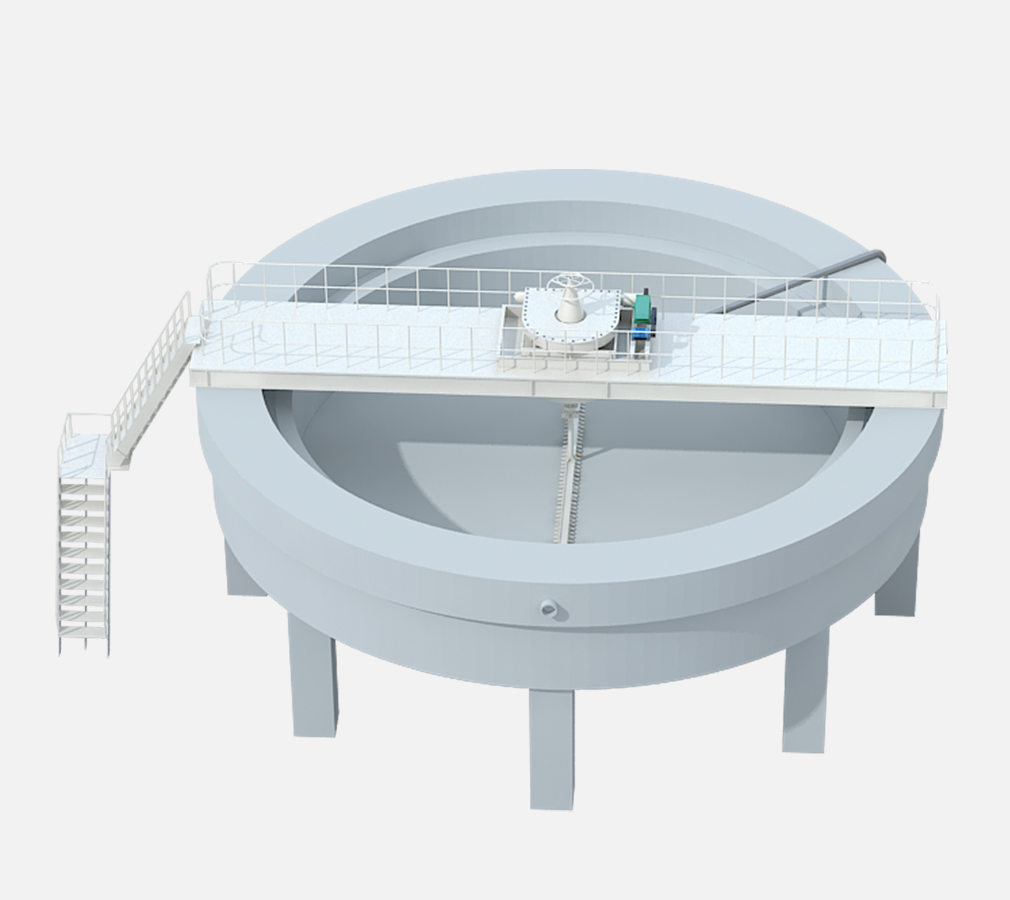

The sedimentation mineral thickener represents an innovative dehydration apparatus amalgamating the attributes of precipitation and filtration. Its application spans across various sectors including mining, metallurgy, coal, chemical industry, and environmental protection.

Our high-efficiency thickener concentrators can effectively remove moisture from concentrates and tailings in mineral processing plants, increasing the slurry concentration from 20%–30% to approximately 40%–70%. This leads to cleaner production and environmental protection.

Get the Latest PriceThe applicable materials for industrial thickener concentrators typically include minerals such as coal, iron ore, copper, gold, and other types of ores, as well as various chemical and industrial slurries.

| Specification | Concentration pond (m) | Deposit square(m2) | Harrow part | Motor | Processing capacity (t/d) | Total weight(t) | |||||

| Model | Specification | Inner diameter | Depth | Pond degree | Method | Height(m) | Rotation time(min/r) | Driving | Lifting | ||

| NZS-1 | Φ1.8m | 1.8 | 1.8 | 2.54 | Manual | 0.16 | 2 | Y90L-6 1.1KW | ---- | 5.6 | 1.9 |

| NZS-3 | Φ3.6m | 3.6 | 1.8 | 10.2 | Manual | 0.35 | 2.5 | Y90L-6 1.1KW | ---- | 22.4 | 4.3 |

| NZS-6 | Φ6m | 6 | 3 | 28.3 | Manual | 0.2 | 3.7 | Y90S-4 1.1KW | ---- | 62 | 10.7 |

| NZSF-6 | Φ6m | 6 | 3 | 28.3 | Manual | ---- | 3.7 | Y90S-4 1.1KW | ---- | 62 | 5.1 |

| NZ-9 | Φ9m | 9 | 3 | 63.6 | Auto | 0.25 | 4.34 | Y132S-6 3KW | XWD0.8-3 0.8KW | 140 | 8.5 |

| NZS-9 | Φ9m | 9 | 3 | 63.6 | Manual | 0.25 | 4.34 | Y132S-6 3KW | ---- | 140 | 7.5 |

| NZS-12 | Φ12m | 12 | 3.5 | 113 | Manual | 0.25 | 5.28 | JTC752A-44 5.2KW | ---- | 250 | 11.1 |

| NZ-15 | Φ15m | 15 | 4.4 | 176 | Auto | 0.4 | 10.4J | JTC752A-44 5.2KW | Y112M-6 2.2KW | 350 | 26.0 |

| NZ-20 | Φ20m | 20 | 4.4 | 314 | Auto | 0.4 | 10.4 | Y100L1-4 5.2KW | Y112M-6 2.2KW | 960 | 28.9 |

| NZ-30 | Φ30m | 30 | 7.165 | 707 | ---- | 0.61 | 13.7 | Y672A-44 5.2KW | YCJ132-S 1.5KW | ---- | 36.6 |

| NZS-45 | Φ45m | 45 | 4.633 | 1590 | Manual | ---- | 20 | Y672A-44 5.2KW | YCJ160-S 2.2KW | 515 | 54.4 |

| NT-15 | Φ15m | 15 | 3.5 | 177 | ---- | ---- | 8.4 | Y132M2-6 5.5KW | ---- | 390 | 12.6 |

| NQ-18 | Φ18m | 18 | 3.5 | 255 | ---- | ---- | 10 | Y132M2-6 5.5KW | ---- | 560 | 11.6 |

| NQ-24 | Φ24m | 24 | 3.4 | 452 | ---- | ---- | 12.7 | Y160M-6 7.5KW | ---- | 1000 | 26.6 |

| NQ-30 | Φ30m | 30 | 3.6 | 707 | ---- | 16 | Y160M-6 7.5KW | ---- | 1570 | 30.9 | |

| NJ-38 | Φ38m | 38 | 4.9 | 1134 | ---- | ---- | 10-25 | JZT252-4 11KW | Y160M-6 7.5KW | 1600 | 63.3 |

| NT-45 | Φ45m | 45 | 5.05 | 1590 | Auto | ---- | 19.3 | Y160L-6 11KW | ---- | 2400 | 66.8 |

| NTJ-53 | Φ53m | 53 | 5.07 | 2202 | ---- | ---- | 23.18 | Y180L-6 15kw |

---- | 6250 | 89.1 |

| NT-100 | Φ100m | 100 | 5.65 | 7846 | ---- | ---- | 43 | Y180L-6 15KW | ---- | 3030 | 214.9 |

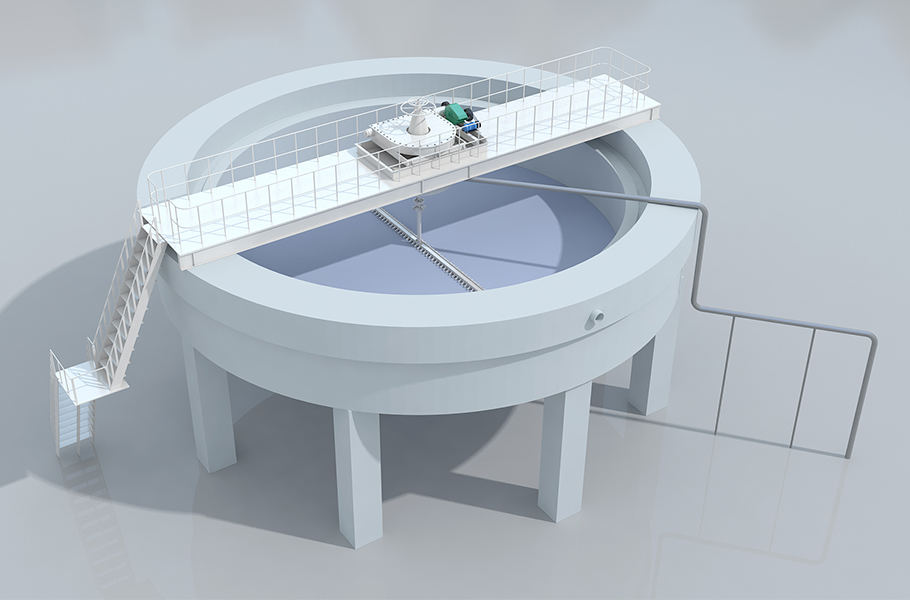

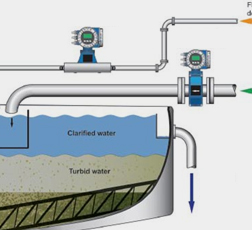

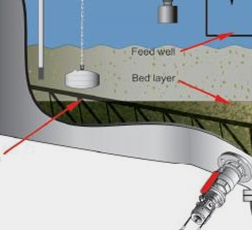

The thickener starts by removing gas and blending the slurry with a flocculant. Next, the mixture goes into a high-concentration sedimentation zone where small particles combine and sink, while clear water flows out. Finally, a central drive unit moves the concentrated material to the discharge point.

The feeding pipe is strategically positioned below the liquid level and angled to prevent gas from entering the ore, which could otherwise cause blockages in the system.

Polyacrylamide, a flocculant, is introduced to the process to increase the size of solid particles and accelerate their settling, thereby improving the efficiency of separation.

The high-efficiency concentrator employs inclined plates to shorten the falling distance of particles, increase surface area, and improve clarification, thereby enhancing the concentration process.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.