The sand making machine is a machine that crushes rocks into sand particles, providing high-quality sand for construction projects like high-rise buildings, highways, and concrete mixing plants, replacing natural sand.

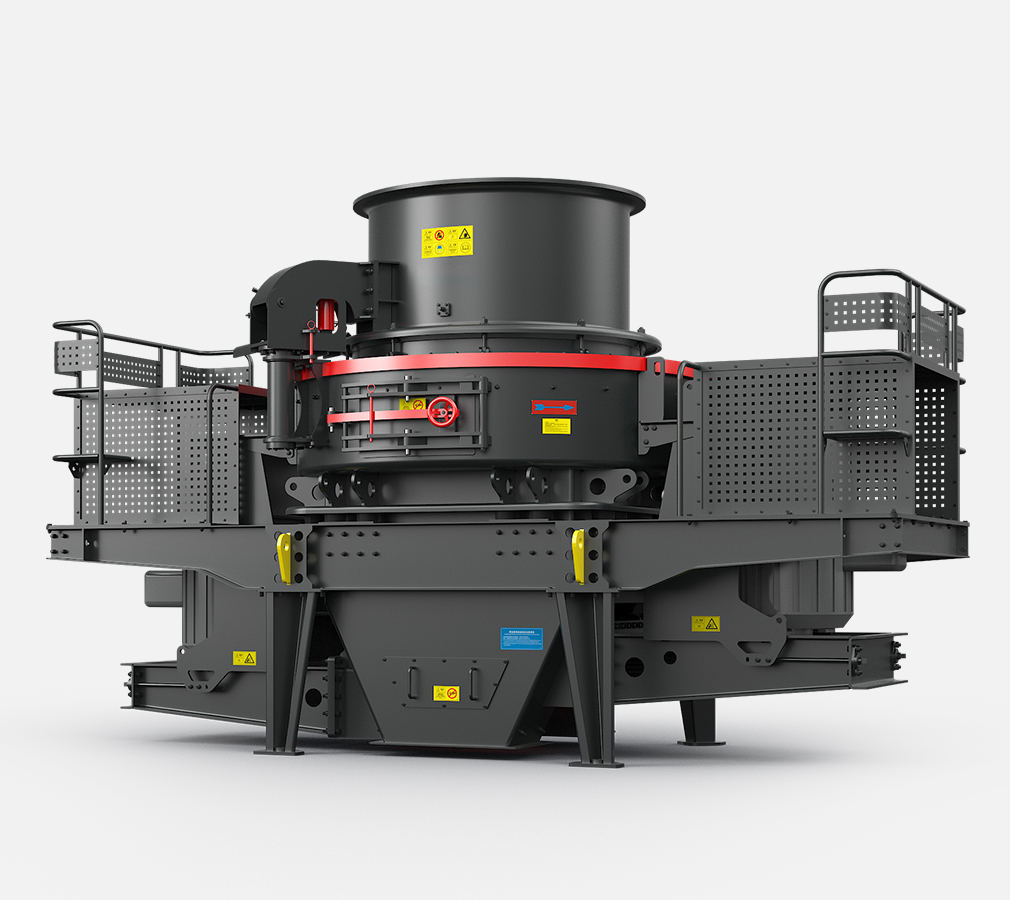

Our sand making machines meet different needs: HVI models offer best-in-class sand making, VSI models offer cost-effective solutions with flexible feed options and higher throughputs, while mobile models allow on-site mobility Sand making.

Get the Latest PriceOur sand makers are designed for materials with a maximum hardness of 320 MPa, including pebble, granite, basalt, iron ore, limestone, quartz, slag, refractory materials, and others.

| Model | Hard material | Soft material | Sand Shaping | Sand Making | Motor Power(kw) |

| Max.Feeding Size (mm) | Throughput(t/h) | ||||

| HVI 0815 | <30 | <35 | 50-140 | 90-230 | 2×75 |

| HVI 0818 | <30 | <35 | 60-190 | 110-283 | 2×90 |

| HVI 0922 | <35 | <40 | 70-210 | 150-330 | 2×110 |

| HVI 0926 | <35 | <40 | 85-240 | 170-380 | 2×132 |

| HVI 1032 | <40 | <45 | 130-278 | 180-400 | 2×160 |

| HVI 1040 | <40 | <45 | 180-284 | 250-440 | 2×200 |

| HVI 1263 | <50 | <55 | 320-498 | 370-585 | 2×315 |

| Model | VSI 7611 | VSI 8518 | VSI 9526 | VSI 1140 | VSI 1145 | VSI 1150 | |

| Capacity (t/h) |

Feed both at center and sides | 80-180 | 140-260 | 200-380 | 300-520 | 350-610 | 360-650 |

| Feed at center | 40-90 | 70-130 | 100-190 | 160-260 | 180-355 | 190-365 | |

| Max.feeding size (mm) |

Soft material | 35 | 40 | 45 | 50 | 50 | 50 |

| Hard material | 30 | 35 | 40 | 40 | 45 | 45 | |

| Rotation speed(r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1150-1300 | 1150-1300 | 1150-1300 | |

| Motor power(kw) | 4P 110 | 4P 180 | 4P 264 | 4P 400 | 4P 440 | 4P 500 | |

| Overall dimension(L×W×H)(mm) | 4100×2250×2300 | 4160×2360×2500 | 4540×2500×2830 | 5500×2750×3100 | 5500×2750×3100 | 5500×2750×3100 | |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

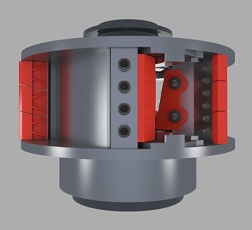

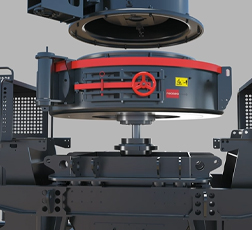

A sand making machine, also known as a vertical shaft impact crusher, uses high-speed rotation and friction to crush materials into desired sizes. It throws material against a hard surface to break it into smaller pieces, which then collide with each other to further reduce size and create sand particles of varying shapes.

The equipment is small in size, facilitating easy installation and maintenance, making it suitable for various settings.

It boasts a large crushing ratio, high sand production ratio, and delivers cubic finished products, ensuring efficient and effective operation.

Constructed with high-quality steel parts, including a protective plate that can be flipped after wear, and utilizing thin oil lubrication to extend its service life.

Featuring a high degree of automation, it minimizes dust and noise pollution, while also conserving energy and promoting environmental protection.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.