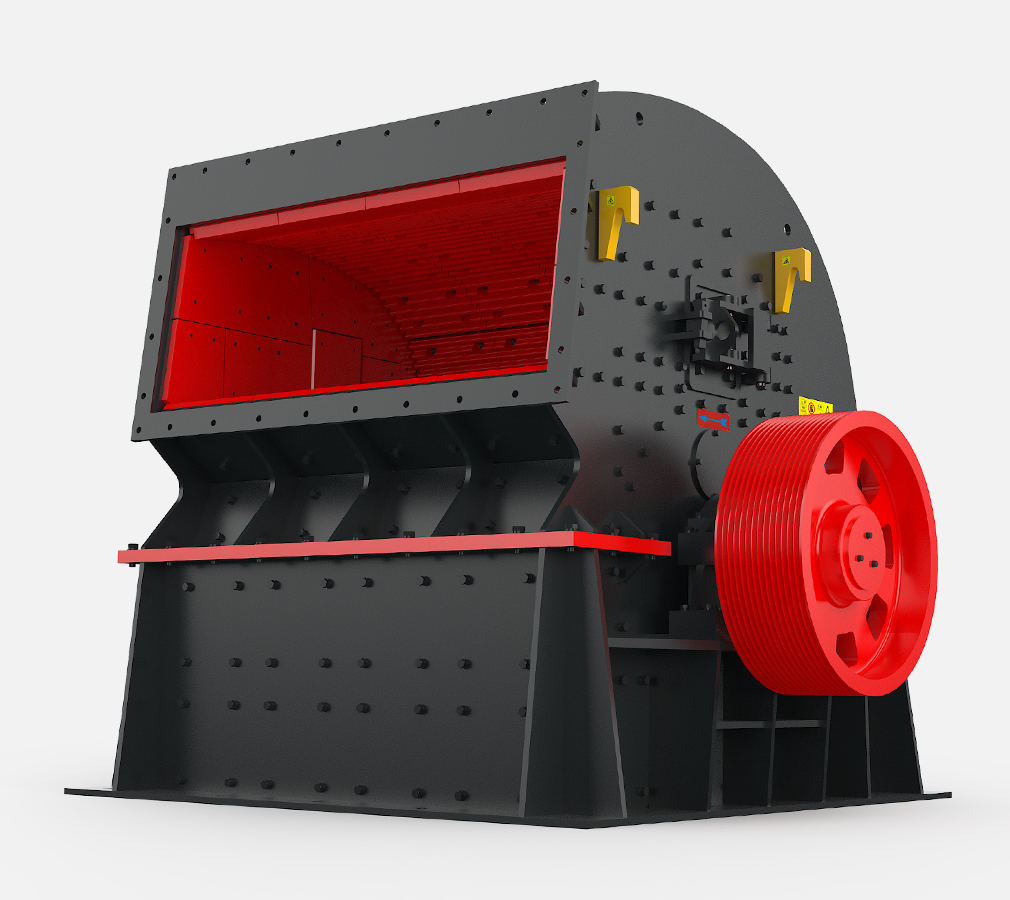

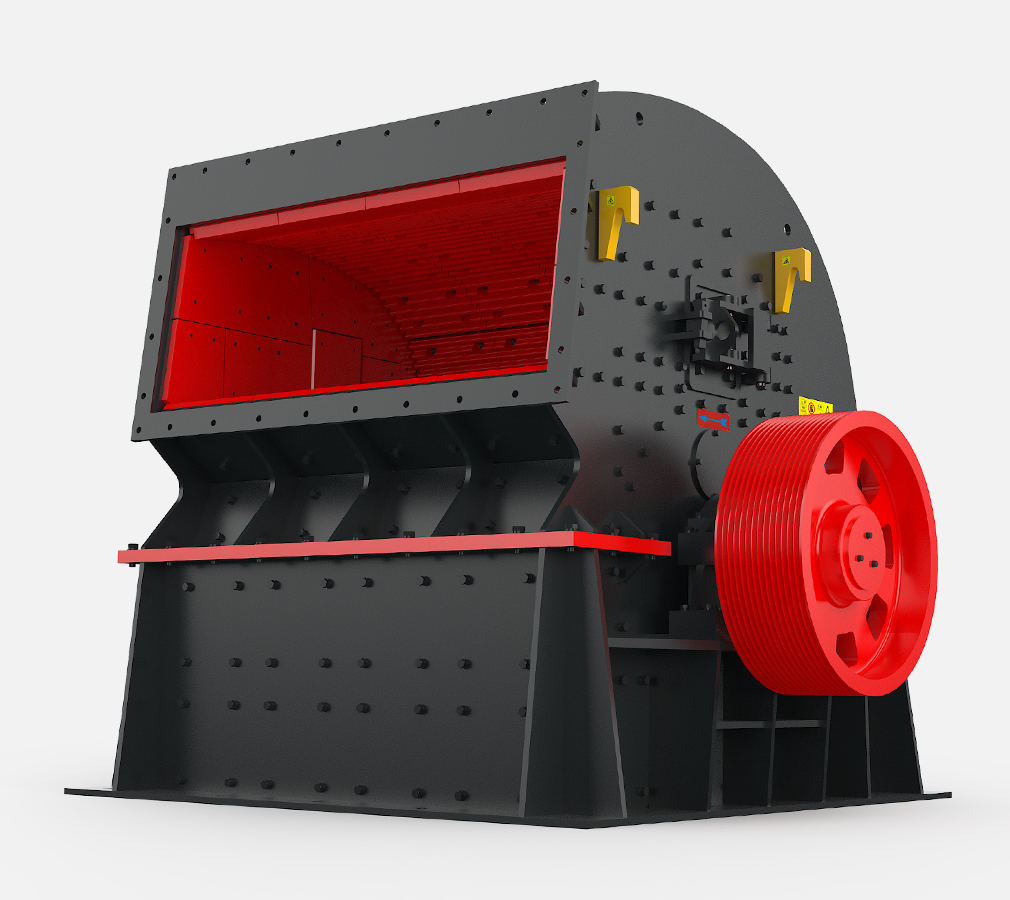

The heavy hammer crusher is an upgraded version of the ordinary one, capable of crushing materials into fine particles in one go for large-scale production.

Our heavy hammer crushers are available in two models: PCZ and PCX. The PCZ has a larger feed size and a capacity 3 times that of an impact crusher, making it an ideal choice for high-production crushing lines. The PCX series has a shaping effect because the discharge particle size is finer.

Get the Latest PriceThe heavy hammer crusher is specially designed to crush brittle materials with hardness not exceeding 200 MPa and moisture content not exceeding 15%, such as limestone, dolomite, bluestone, coal, coal gangue, etc.

| Model | Rotor diameter×length (mm) | Feed Opening Length×width(mm) | Feeding Size (mm) | Processing Capacity(t/h) | Power (kw) | Dimensions L×W×H (mm) |

| PCZ1308 | Φ1330×790 | 870×780 | ≤380 | 60-160 | 132 | 2880×2130×2390 |

| PCZ1410 | Φ1400×1000 | 1060×740 | ≤450 | 80-210 | 2×90(160) | 2830×2100×2485 |

| PCZ1610 | Φ1600×1000 | 1090×930 | ≤480 | 100-230 | 2×132 | 3370×2415×2750 |

| PCZ1612 | Φ1600×1200 | 1340×1140 | ≤500 | 120-350 | 2×160 | 3370×2613×2750 |

| PCZ1615 | Φ1600×1500 | 1570×1140 | ≤550 | 200-550 | 2×200 | 3370×2925×2750 |

| PCZ1716 | Φ1700×1600 | 1420×1200 | ≤600 | 400-850 | 2×250 | 3520×3000×3210 |

| PCZ1720 | Φ1700×2000 | 2030×1200 | ≤650 | 500-1000 | 2×400 | 3670×3390×3330 |

| PCZ1920 | Φ1900×2000 | 1980×1210 | ≤750 | 800-1500 | 2×500 | 4490×3910×3600 |

| PCZ2225 | Φ2200×2500 | 2530×1610 | ≤1000 | 1500-3000 | 1250 | 4890×5010×4560 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

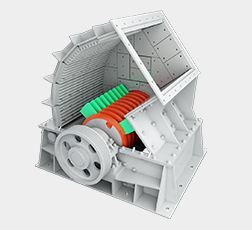

The motor spins the rotor rapidly in the crushing cavity. Materials are fed into the crusher and crushed by the hammers. A sieve plate at the rotor's bottom allows for adjusting the output size by changing the grate gap. Smaller crushed material passes through the sieve plate, while larger pieces are continuously ground by the rotor until fully crushed.

The heavy hammer crusher combines crushing and shaping in one step, eliminating primary crushing.

The crusher features a simple, durable structure with a large feed size and a high efficiency.

The crusher offers adjustable finished materials with uniform particles and strong compressive strength.

The crusher has a versatile use for various applications, such as stone crushing, sand making, and mineral processing.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.

CHAT ONLINE

CHAT ONLINE TOP

TOP