The mobile crusher integrates crushing, screening, sand making and shaping. It is mainly used in mining, coal, construction waste, construction sites, road construction, and other industries. It is highly mobile and can replace fixed crushing stations.

Wheel type mobile crusher: Semi-mobile, towed by vehicles; used in construction waste disposal, urban facilities, and road construction industries; the power mode is to use mains electricity if possible, and use generators in wilderness areas.

Crawler type mobile crusher: Completely mobile (hydraulic driven crawler), wireless remote control operation; used in harsh environments such as mountains, wetlands, and climbing; the power mode is a hybrid of gasoline and electricity.

Get the Latest PriceMobile crushing stations can be used for mining crushing, sand making and municipal solid waste recycling:

Coal gangue, iron ore, granite, basalt, diabase, limestone, river pebbles, calcite, quartz, cement clinker, concrete, construction waste, tailings, slag, etc.

| Model | FTM938HD86 | FTM1149HD98 | FTM1349HD110 | FTM1349HD125 |

| Transportation lenght(mm) | 12600 | 13500 | 14500 | 15200 |

| Transportation Width(mm) | 2600 | 2700 | 2800 | 2900 |

| Transportation Height(mm) | 3870 | 4200 | 4450 | 4500 |

| Maximum Lenght(mm) | 12500 | 14000 | 16100 | 16700 |

| Maximum Width(mm) | 4100 | 4500 | 5100 | 5100 |

| Maximum Height(mm) | 4100 | 4900 | 5000 | 5300 |

| Weight(t) | 39 | 57 | 55 | 65 |

| Tire Configuration | Dualaxial | Triaxial | Triaxial | Triaxial |

| Jaw Crusher | HD86 | HD98 | HD110 | HD125 |

| Maximum Feeding Size(mm) | 500 | 550 | 660 | 800 |

| Discharge opening range | 50-150 | 75-175 | 100-200 | 125-225 |

| Capacity(t/h) | 85-275 | 110-350 | 215-510 | 280-650 |

| Vibrating Feeder | ZSW380×95 | ZSW420×110 | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B800×8.5m | B1000×9.5m | B1000×11m | B1200×11m |

| Side-opening Belt conveyor(optional) | B500×3m | B650×3.5m | B650×4m | B650×4m |

| Gensrt(optional) | 200KW | 250KW | 270KW | 400KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-10 | RCYD(C)-12 |

| Model | FTM3S185GYS300 | FTM3S216GYS400 | FTM3S216HP300 |

| Transportation length(mm) | 14500 | 15000 | 16000 |

| Transportation Width(mm) | 3000 | 3000 | 4550 |

| Transportation Height(mm) | 4400 | 4500 | 4600 |

| Maximum Length(mm) | 17000 | 16000 | 17000 |

| Maximum Width(mm) | 3400 | 3900 | 6900 |

| Maximum Height(mm) | 5800 | 6500 | 4700 |

| Weight(t) | 34.5 | 49.5 | 41 |

| Tire Configuration | Dualaxial | Triaxial | Triaxial |

| Cone crusher | GYS300 | GYS400 | HP300 |

| Discharging belt Conveyor | B650×15M×2 | B800×15M×2 | B800×15M×2 |

| Return belt conveyor | B650×14M | B800×14M | B800×16M |

| CONveyor Belt For Final Products | B500×15M | B800×6M | B650×15M×2 |

| Under Virbrating Screen | B800×7M | B800×8M | B800×9M |

| Vibrating Screen | 3YK1854 | 3YK2160 | 3YK2160 |

| Model | FTM938F1210 | FTM938F1214 | FTM1149F1315 | FTM938F1110 | FTM1349F1315 |

| Transportation length(mm) | 12000 | 12000 | 13900 | 15450 | 15450 |

| Transportation Width(mm) | 2550 | 2550 | 2900 | 2950 | 2950 |

| Transportation Height(mm) | 3900 | 3900 | 4450 | 4500 | 4500 |

| Maximum length(mm) | 12500 | 12500 | 13900 | 15450 | 15450 |

| Maximum Width(mm) | 3250 | 3260 | 3250 | 3250 | 3250 |

| Maximum Height(mm) | 5100 | 5200 | 5200 | 5200 | 5200 |

| Weight(t) | 39 | 44 | 54 | 62 | 62 |

| Impact crusher | PE-1210 | PE-1214 | PF-1315 | HD1110 | HD1315 |

| Maximum Feeding Size(mm) | 350 | 350 | 500 | 400 | 700 |

| Capacity(t/h) | 70-130 | 100-180 | 130-250 | 112 | 280 |

| Vibrating Feeder | ZSW950×3800 | ZSW950×3800 | ZSW110×4900 | ZSW130×4900 | ZSW130×4900 |

| Main Belt Conveyor | B800×8.5M | B800×8.5M | B1000×9.5M | B800×11M | B1200×11M |

| Side-opening Belt conveyor(optional) | B500×3.2m | B500×3.2m | B650×4m | B650×4m | B650×4m |

| Gensrt(optional) | 320KW | 320KW | 400KW | 320KW | 440KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-8 | RCYD(C)-12 |

The mobile crusher has multiple configurations (feeder + crusher/sand making machine + vibrating screen) to form a coarse crushing, medium and fine crushing and screening station. For soft materials, it uses hammer crusher or jaw crusher + impact crusher. For hard materials, it uses jaw crusher + cone crusher. For making sand, it uses crusher + sand making machine.

With compact structure and small turning radius, it can be moved directly to urban highways, construction sites, wetlands and other places for operation.

Different feeders, crushers, screening equipment and sand making machines can be configured individually according to user needs to form an efficient coarse crushing, medium crushing and fine crushing production line.

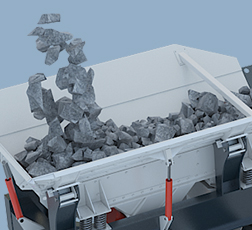

It adopts a large-capacity double-layer thickened feeder silo to control the feeding amount with frequency conversion. Finely divided materials are pre-screened to increase the production capacity.

Fully automatic control, equipped with high-performance host, independent electronic control system and hydraulic support guard. Therefore, it is easy to install, replace parts and perform repairs.

The equipment is durable and equipped with advanced motors and power systems to meet normal operation requirements under power outage conditions and ensure continuous production. It is also equipped with a noise reduction and dust removal system to achieve environmentally friendly production.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.