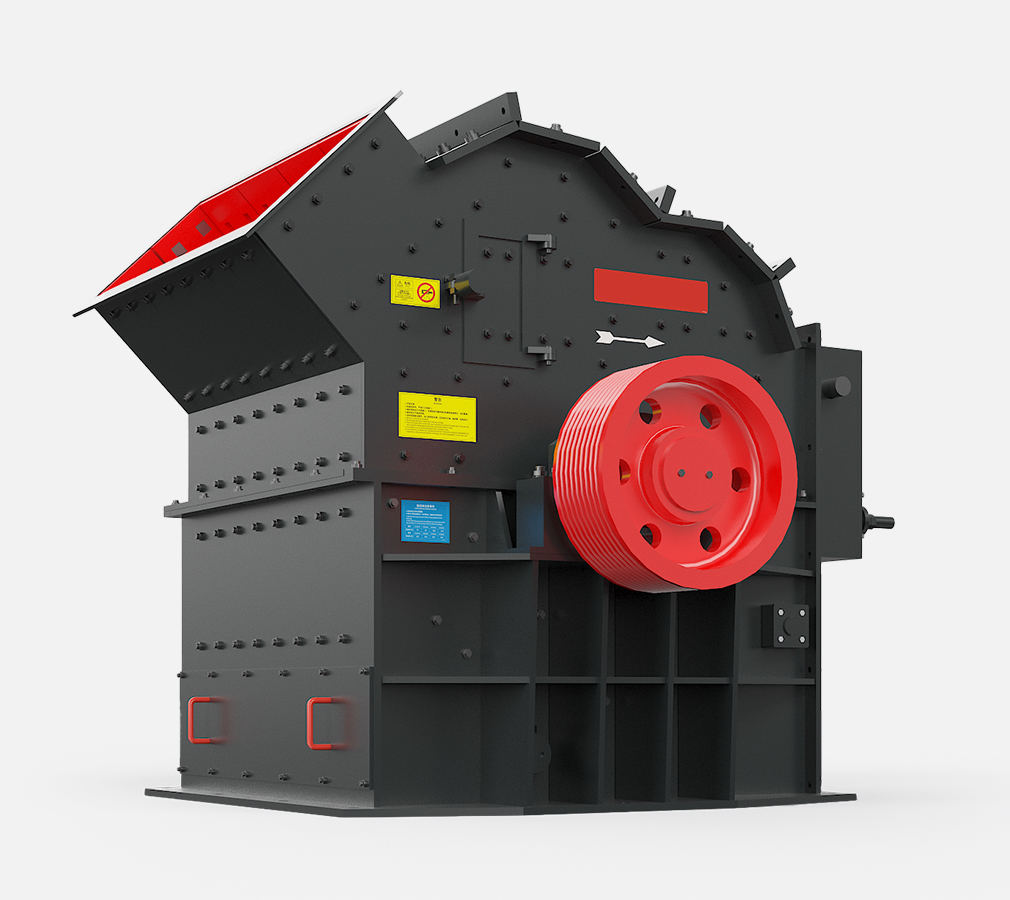

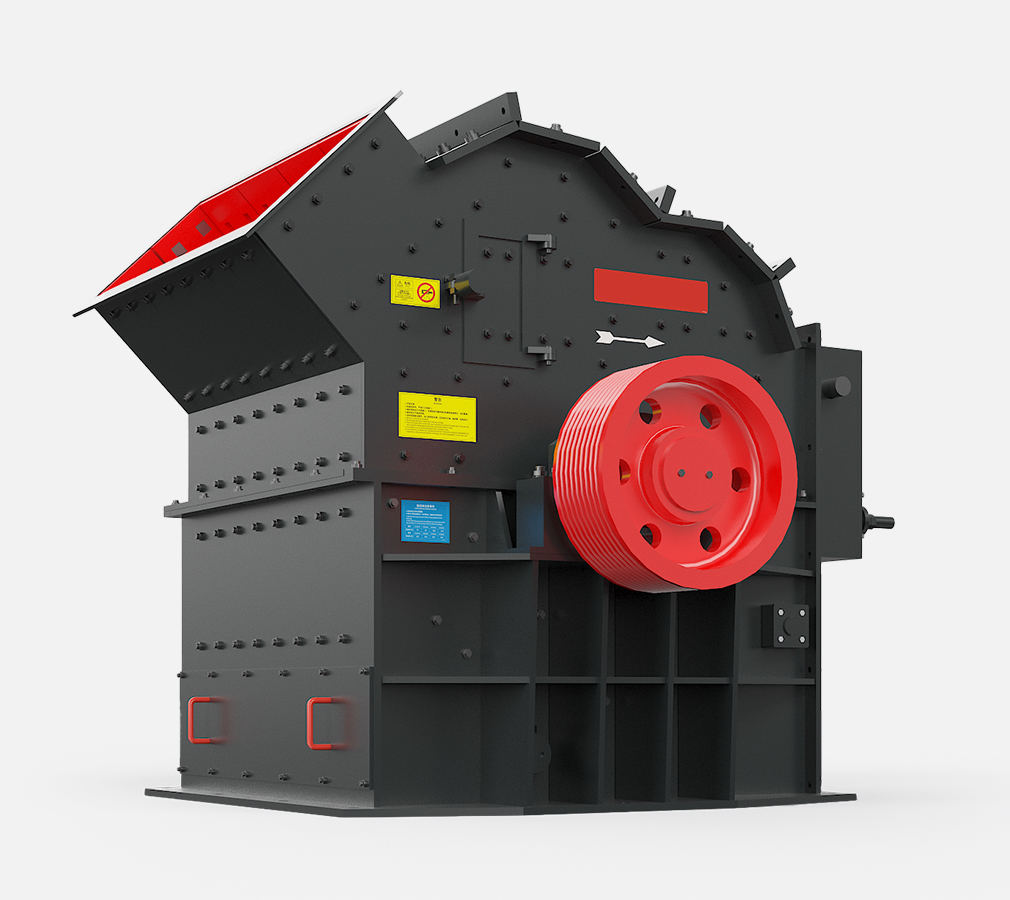

The high-efficiency fine crusher is a new crusher that uses the high-speed impact to perform medium and fine crushing operations. It is often used in crushing and sand making plants and can crush 90% of the finished products to less than one centimeter at a time.

Our fine crushers are energy-efficient and efficient, and can be used in conjunction with trommel screens and sand washers to produce finished granules that meet construction sand standards.

Get the Latest PriceThe fine crusher is suitable for brittle materials with a hardness of less than 9, such as river pebbles, cement clinker, limestone, granite, quartz, feldspar, calcite, marble, kaolin, coal, iron ore, and gypsum.

| Model | PXJ0804 | PXJ0806 | PXJ0808 | PXJ1010 | PXJ1212 | PXJ1414 | PXJ1616 | PXJ1818 |

| Rotor diameter×width(mm) | 800×400 | 800×600 | 800×800 | 1010×1010 | 1200×1200 | 1400×1400 | 1600×1600 | 1800×1800 |

| Limestone(t/h) | 5-45 | 7-55 | 10-65 | 15-75 | 20-110 | 25-150 | 30-200 | 40-260 |

| Power(kW) | 37 | 45 | 45 | 55 | 110 | 160 | 250 | 315 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

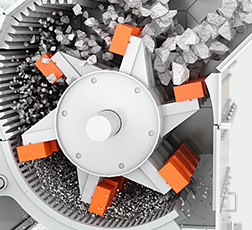

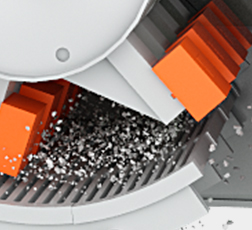

The motor-powered fine crusher uses a high-speed rotating rotor to crush materials. As materials enter the crushing cavity, they're crushed by the rotor's plate hammer and propelled towards the impact plate. Successive crushing and grinding produce ultra-fine results before discharge. Output size can be adjusted using the grate bar and rear gap (rotor and liner) at the outlet, with productivity improvements possible by adjusting the rear gap.

First-level crushing with exceptional fine crushing capability, merging second- and third-level crushing for a high crushing ratio (25-30).

Enhanced crushing efficiency through grate plates, rigid solid rotor body, and hard extrusion crushing mechanism.

Adjustable discharging granularity facilitated by multi-element alloy bottom screen plate and impact frame, resulting in well-shaped output with a high proportion of cubic products.

Long-lasting high chromium alloy hammer head paired with high manganese or carbon steel handle, minimizing overall wear and extending service life, with only the hammer head needing replacement.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.