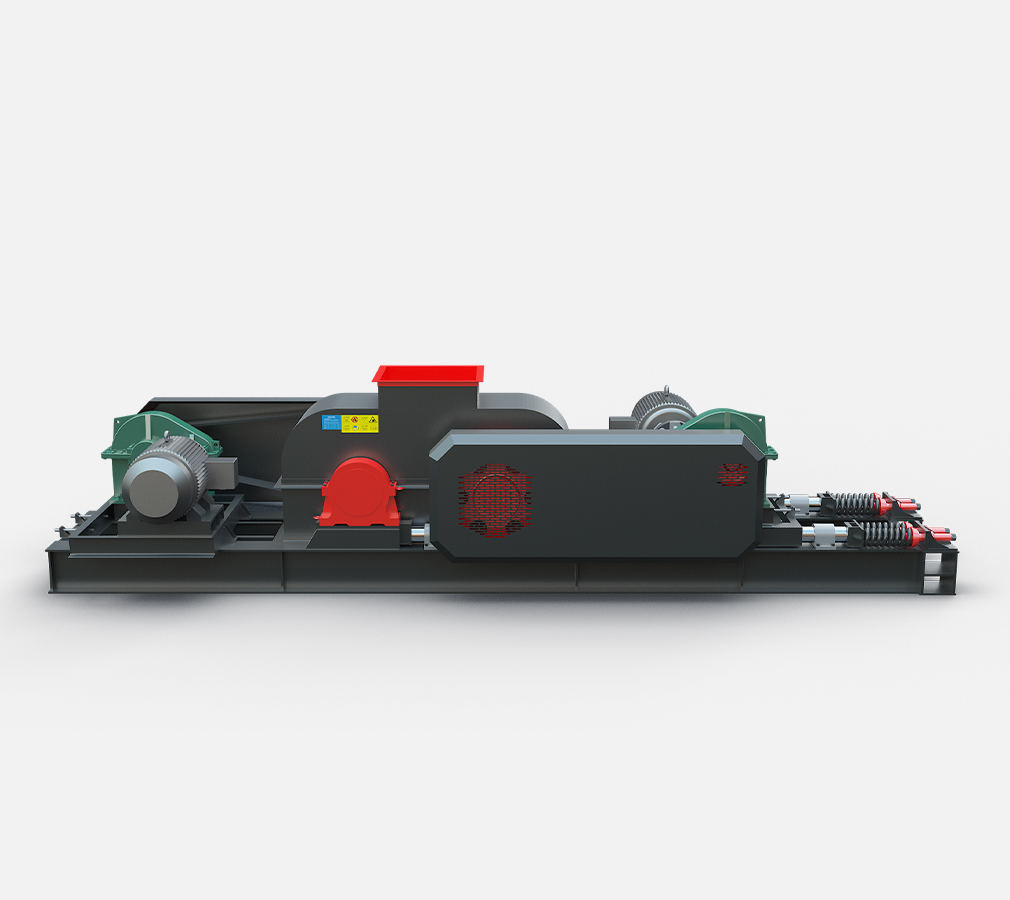

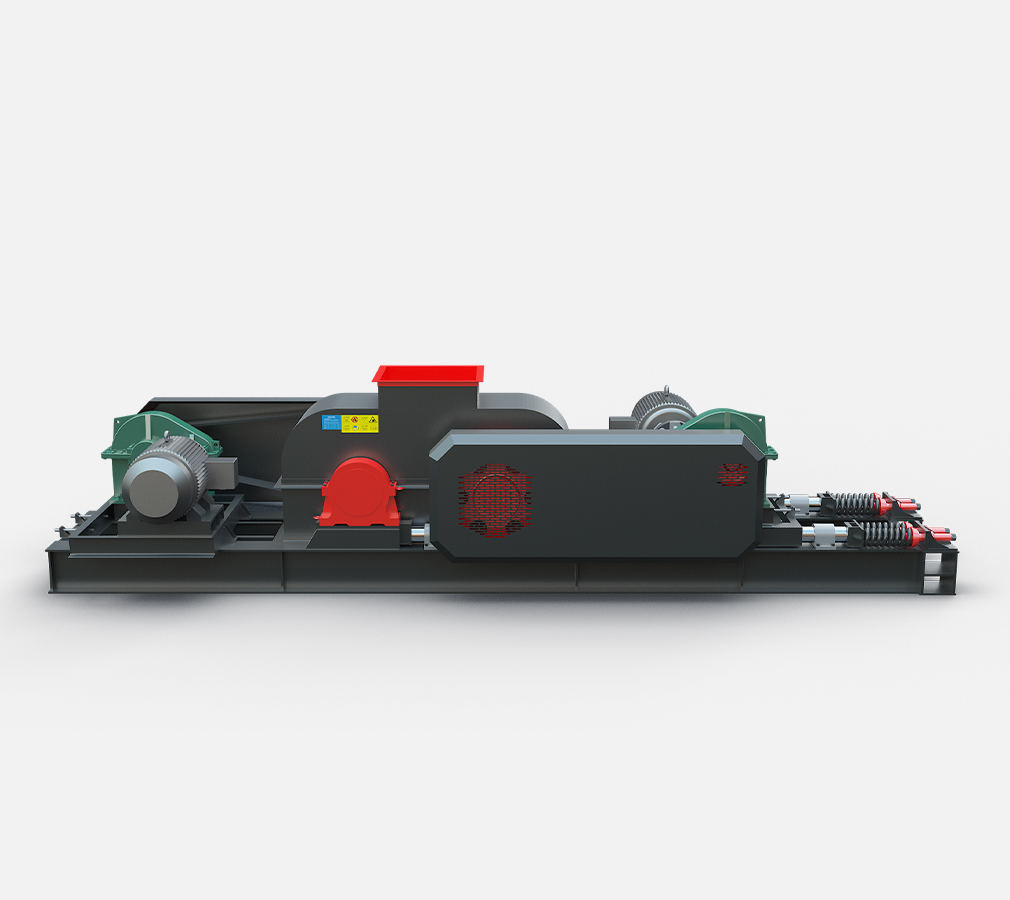

The roll crusher is also called the double roll crusher or double toothed roll crusher. It is the most economical and practical secondary or tertiary crusher in small and medium stone crushing plants.

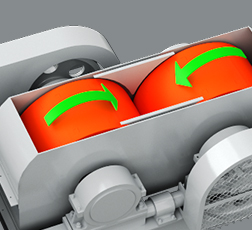

The double toothed roller crusher uses two independently driven rollers to crush materials through squeezing, grinding, and shear forces, and easily removes adhered materials from the rollers.

It comes in two types: smooth roll crusher and toothed roller crusher. The toothed roller crusher enhances splitting action for coarse crushing or improved crushing ratio.

Get the Latest PriceThe double toothed roller crushers are suitable for crushing brittle materials with medium hardness and below and compressive strength less than 160 MPa, especially various minerals, viscous materials, coal, cement clinker, slag, glass, etc.

| Model | 2PG0425 | 2PG0640 | 2PG0740 | 2PG0850 | 2PG1060 | 2PG1260 | 2PG1560 |

| Roller diameter(mm) | Ф400 | Ф600 | Ф700 | Ф800 | Ф1000 | Ф1200 | Ф1500 |

| Roller width(mm) | 250 | 400 | 400 | 500 | 600 | 600 | 600 |

| Input Size(mm) | ≤25 | ≤25 | ≤25 | ≤25 | ≤30 | ≤30 | ≤30 |

| Discharging Gate(mm) | 2-8 | 2-8 | 2-8 | 2-8 | 2-10 | 2-10 | 2-10 |

| Processing capacity(t/h) | 3-10 | 5-20 | 10-30 | 15-40 | 20-50 | 25-70 | 30-110 |

| Power Models | Y132M-6 | Y180L-6 | Y200L-4 | Y225M-4 | Y250M-4 | Y315M-6 | Y315L-6 |

| Motor power(kw) | 5.5×2 | 15×2 | 30×2 | 45×2 | 55×2 | 75×2 | 110×2 |

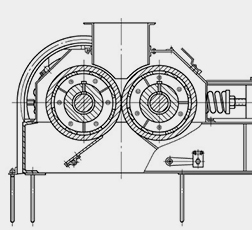

The roller crusher operates with two cylindrical rollers, supported by fixed and movable bearings, driven by a motor to crush material between them. Adjusting the bearings and spring compression can widen the gap to prevent damage when dealing with hard or tough materials.

With two motors delivering ample power, the double roll crusher effortlessly handles high-hardness and high-moisture materials, ensuring smooth operation and high crushing efficiency.

The adjustable distance between the two rollers (1-20 mm) allows for precise control over output size, producing fine particles with minimal over-crushing, thanks to its simple structure and easy operation.

Crafted from high manganese steel, the rollers boast minimal wear and easy replacement, while automatic lubrication and grease-discharging holes in the bearing seat ensure hassle-free maintenance, all at an affordable price with low operating costs.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.