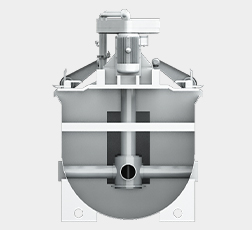

The flotation machine is specialized mineral processing equipment for the treatment of finely grained lean ores. By employing flotation agents, it induces foam formation via chemical interactions with minerals, thereby efficiently eliminating impurities or extracting valuable minerals.

As the main equipment used in the flotation process, the flotation machine has the properties of continuous operation, reliability, low power consumption, wear resistance, and structural structure. It also has functions such as aeration, stirring, and adjustment.

Get the Latest PriceFlotation machines are mainly used to separate gold, silver, copper, iron, lead, zinc, molybdenum, nickel, aluminum and other metal minerals. It can also be used for the selection of non-metallic minerals.

| Category | Specification Model |

Effective cubage (m³) |

Processing capacity (m³/min) |

Main shaft loam board | Dimensions (L×W×H) (m) |

Single trough Weight (t) |

|||

| Power (kw) |

Rotate speed (r/min) |

Rotate speed (r/min) |

Power (kw) |

||||||

| XJK type flotation machine |

XJK-0.35 | 0.35 | 0.18-0.4 | 1.5 | 483 | 25 | 1.1 | 0.7×0.7×0.7 | 0.5 |

| XJK-0.62 | 0.62 | 0.3-0.9 | 3.0 | 400 | 25 | 1.1 | 0.90×0.82×0.85 | 1.0 | |

| XJK-1.1 | 1.1 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1.1×1.1×1 | 1.4 | |

| XJK-2.8 | 2.8 | 1.5-3.5 | 11 | 280 | 25 | 1.1 | 1.75×1.6×1.1 | 2.5 | |

| XJK-5.8 | 5.8 | 5-7 | 22 | 240 | 25 | 1.5 | 2.2×2.2×1.2 | 3.6 | |

| SF type flotation machine |

SF-0.37 | 0.37 | 0.2-0.4 | 1.5 | 386 | 25 | 1.1 | 0.7×0.7×0.75 | 0.5 |

| SF-0.7 | 0.7 | 0.3-0.9 | 3 | 400 | 25 | 1.1 | 0.9×0.82×0.95 | 1.0 | |

| SF-1.2 | 1.2 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1.1×1.1×1.1 | 1.9 | |

| SF-2.8 | 2.8 | 1.5-3.5 | 11 | 268 | 25 | 1.1 | 1.75×1.6×1.15 | 2.6 | |

| SF-4 | 4 | 2-4 | 15 | 220 | 25 | 1.5 | 1.85×2.05×1.2 | 2.9 | |

| SF-8 | 8 | 4-8 | 30 | 191 | 25 | 1.5 | 2.2×2.9×1.4 | 4.2 | |

| SF-10 | 10 | 5-10 | 30 | 191 | 25 | 1.5 | 2.2×2.9×1.7 | 4.5 | |

| SF-20 | 20 | 5-20 | 30×2 | 191 | 25 | 1.5 | 2.85×3.8×2 | 9.9 | |

| JJF type flotation machine |

JJF-2 | 2 | 1-3 | 7.5 | 443 | 25 | 1.5 | 1.4×1.4×1.1 | 1.7 |

| JJF-4 | 4 | 2-4 | 11 | 305 | 25 | 1.5 | 1.6×2.15×1.25 | 2.4 | |

| JJF-8 | 8 | 4-8 | 22 | 233 | 25 | 1.5 | 2.2×2.9×1.4 | 4.5 | |

| JJF-10 | 10 | 5-10 | 22 | 233 | 25 | 1.5 | 2.2×2.9×1.7 | 4.9 | |

| JJF-16 | 16 | 5-16 | 30 | 180 | 25 | 1.5 | 2.85×3.8×1.7 | 8.0 | |

| JJF-20 | 20 | 5-20 | 37 | 180 | 25 | 1.5 | 2.9×3.8×2.0 | 10.5 | |

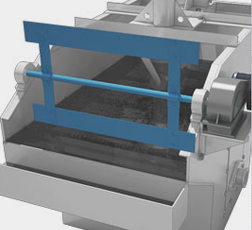

The motor drives the V-belt, rotating the impeller to create centrifugal force and suction. In the flotation machine's operation, it draws in air to mix with the slurry, adding chemicals to create mineralized foam. Adjusting the gate height controls the liquid level, making it easier to extract valuable foam via the upper plate.

The equipment demonstrates excellent foam refinement and flotation effectiveness, ensuring effective separation of various minerals with high utilization rates.

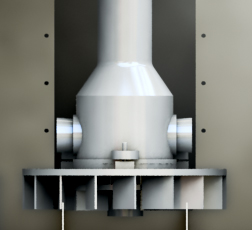

Featuring a closed double-section cone impeller, it facilitates strong downward circulation, while its large air intake ensures low energy consumption, contributing to its efficiency.

Components like the rubber impeller ensure longevity, reducing the need for frequent replacements. Additionally, the reasonable slurry circulation minimizes coarse sand deposition, further enhancing its durability.

The equipment offers easy adjustment through automatic and electric controls for slurry level, along with independent flotation circuits in each tank, eliminating the need for extra equipment. Its horizontal configuration allows for straightforward process changes.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.