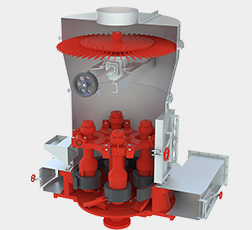

The ultrafine mill represents a cutting-edge advancement in enhancing the efficiency of Raymond mills. Equipped with a high-pressure spring mechanism, it ensures superior grinding performance. Additionally, its adjustable air separator enables precise control over powder fineness, rendering it perfect for the production of micro and fine powders.

Ultra-fine mills mainly produce fine powder and ultra-fine powder for use in mining, ceramics, steel, coal, fertilizer, metallurgy, building materials, power plant desulfurization, chemical industry and other industries.

Get the Latest PriceUltrafine grinding mill is suitable for minerals (diatomite, dolomite, limestone, phosphate rock, etc.), coal, ceramics, glass, cement clinker and other materials with Mohs hardness below 9.3 and humidity not exceeding 8%.

| Type | HGM100 | HGM120 | HGM130 | HGM160 | HGM175 |

| Feeding size (mm) |

<20 | <20 | <25 | <30 | <35 |

| Size of finished product (mm) |

0.25-0.015 | 0.25-0.015 | 0.25-0.015 | 0.25-0.015 | 0.25-0.015 |

| Shift output of different material fineness (t/h) |

0.8-6 | 1.2-8 | 1.8-12 | 2.8-20 | 3.5-25 |

| Rotate speed of central shaft (r/min) |

140 | 140 | 105 | 82 | 75 |

| Diameter of pulverizing ring (mm) |

1075×200 | 1280×240 | 1400×240 | 1770×280 | 1900×300 |

| Diameter of pulverizing roller (mm) |

320×200 | 370×240 | 410×240 | 450×280 | 500×300 |

| Main Motor (kw) |

37 | 55 | 75 | 132 | 160 |

| Fan Motor (kw) |

45 | 55 | 75 | 132 | 160 |

| Analyzer motor (kw) |

11 | 15 | 18.5 | 22 | 30 |

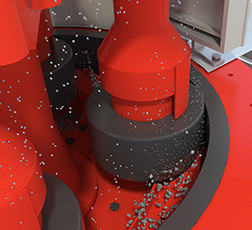

Crushed materials are sent to the ultra-fine mill for grinding. Inside the mill, the grinding roller crushes and grinds the material against the grinding ring. Fine particles are collected by cyclone collectors, aided by air separators and blowers, while coarse material is reclaimed for further grinding. Dust collectors control emissions and remove excess dust to prevent clogs.

The equipment boasts a compact design, ensuring 24/7 operation with minimal energy consumption.

Utilizes high-pressure spring technology for improved output, delivering finer and more consistent grinding results.

Features a turbo-type air separator and variable frequency motor for precise fine powder classification, resulting in a uniform and impurity-free finished product.

Incorporates wear-resistant alloy materials for easy maintenance of grinding components, along with advanced seals that extend lubrication cycles, reduce noise, and effectively eliminate dust.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.