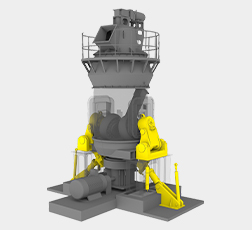

The vertical grinding mill integrates grinding and drying functions.

It has the significant advantages of fine powder and high output, and is mainly used for milling in electric power, metallurgy, construction, chemical industry, and other industries.

HLM series vertical grinding mill is a large-scale, high-yield, energy-saving grinding product that adopts advanced material bed grinding and partial external circulation technology.

It integrates grinding, classification, drying, and transportation.

Get the Latest PriceThe vertical roller mill is suitable for grinding cement clinker, coal, limestone, calcite, dolomite, marble, gypsum, barite, talc, phosphate, kaolin, bentonite, bauxite, graphite, petroleum coke, fly ash, water Slag, slag, and other materials.

| Specifications | Capacity(t/h) | The finished product fineness | The raw material moisture | The finished product moisture | Main motor power(kW) |

| HLM1300K | 10-40 | 0.84-0.37mm (20-400 mesh) | ≤15% | ≤1% | 200 |

| HLM1500K | 13-50 | 280 | |||

| HLM1700K | 18-70 | 400 | |||

| HLM1900K | 20-85 | 500 | |||

| HLM2200K | 35-135 | 800-900 | |||

| HLM2400K | 40-160 | 900-1120 | |||

| HLM2800K | 50-200 | 1120-1250 | |||

| HLM3400K | 70-260 | 1800-2000 | |||

| HLM3700K | 90-320 | 2500-2800 |

Note: The grindability (Bond) index of raw materials is less than or equal to 13kw/t

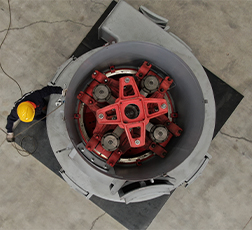

Material enters the mill and is crushed between the rotating grinding roller and disc without direct contact. Hot air removes moisture, extracting powder, while a classifier separates and collects fine particles as the end product.

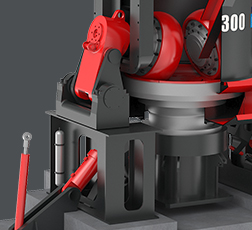

The grinder's roller cover doubles service life, while its large grinding area ensures high efficiency and low energy use. Flexible hydraulic pressure adjustment boosts output.

Dynamic powder separator ensures good particle shape with 97% screen pass rate at 10-40μm. Short material residence time reduces repeated grinding for stable quality.

Strong internal hot air-drying capability ensures uniform particle size.

Easy to operate and maintain. External independent thin oil lubrication station makes oil change convenient.

The hydraulic maintenance device facilitates the replacement of grinding roller sleeves and the maintenance of grinding rollers.

It occupies about 50% of the ball mill and can be arranged in the open air to reduce construction costs.

Fully sealed and environmentally friendly operation with low noise and no dust.

Equipped with hot air-drying function, saving a set of drying equipment.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.