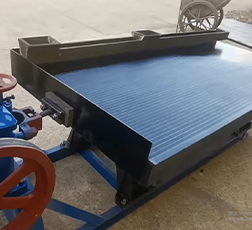

The shaker table is a gravity separation equipment that uses gravity to sort fine-grained materials.

It has different effective recycling particle sizes. The maximum feed particle size is 2 mm for coarse ore, 0.5 mm for fine ore, and 0.15 mm for coal slime.

The shaker table proves highly effective as a gravity separator tailored for fine-grained minerals. Its operational prowess lies in the synchronized interplay of mechanical vibration and water washing, facilitating the segregation of minerals based on their varying densities.

Get the Latest PriceThe shaking table is ideal for separating materials characterized by significant differences in ore density, including: coal, slime, metal ores (gold ore, tin ore, etc), and non-metallic minerals (talc, limestone, garnet, etc).

| Name | Grit concentrator table |

Fine sand concentrator table |

Sludge concentrator table |

|

| Bed surface Dimensions |

Length (mm) |

4450 | 4450 | 4450 |

| Driving part Width (mm) |

1855 | 1855 | 1855 | |

| Concentrate part Width (mm) |

1546 | 1546 | 1546 | |

| Max.feeding size(mm) |

2 | 0.5 | 0.15 | |

| Feeding amount (t/d) |

30-60 | 10-20 | 15-25 | |

| Feeding thickness (%) |

25-30 | 20-25 | 15-25 | |

| Stroke (mm) |

16-22 | 11-16 | 8-16 | |

| Frequency (f) |

45-48 | 48-53 | 50-57 | |

| Bed surface Water quantity (t/d) |

80-150 | 30-60 | 10-17 | |

| Bed surface Horizontal obliquity(°) |

2.5-4.5 | 1.5-3.5 | 1-2 | |

| Bed surface Portrait obliquity(%) |

1.4 | 0.92 | ---- | |

| Table board corner(°) |

32-42 | 40 | 42 | |

| Concentrating area(㎡) |

7.6 | 7.6 | 7.6 | |

| Bed surface Length ratio |

2.6 | 2.6 | 2.6 | |

| Shape of side-bed surface |

Rectangle | Zigzag | Triangle | |

| Motor power(kw) |

1.1 | 1.1 | 1.1 | |

| Transmission device |

Eccentricity Linkage | |||

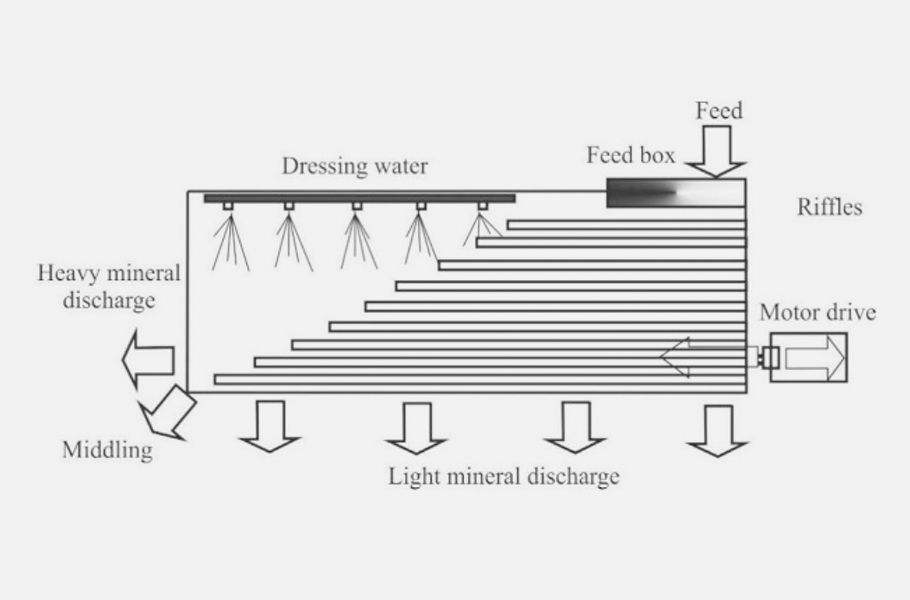

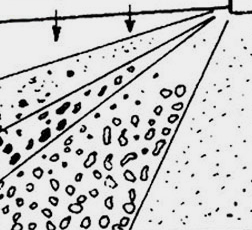

Shaker table mineral processing sorts mineral particles by their specific gravity and sizes using a reciprocating motion on a tilted bed and water flow, separating them into concentrates, medium ores, and tailings.

The shaker table offers high separation efficiency, efficiently yielding final concentrate, medium ore, and tailings in a single separation process, streamlining operations.

It boasts a high beneficiation and enrichment ratio, enhancing the effectiveness of ore processing and resource utilization.

The fan-shaped arrangement of ore on the bed surface facilitates easy observation and adjustment, optimizing the processing workflow and ensuring precise control.

The shaking table, with its sturdy steel frame, fiberglass bed, and specialized grooves, delivers superior performance. It is chemical-free, reducing electricity usage and overall expenses.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.