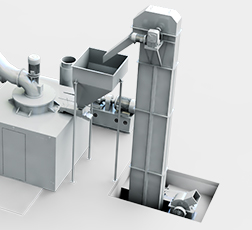

Our bucket elevator serves as a means of vertically transporting powdery, granular, and small-block materials. Widely utilized across industries like construction, cement, coal, chemicals, and power generation, it stands as a highly sought-after transportation equipment.

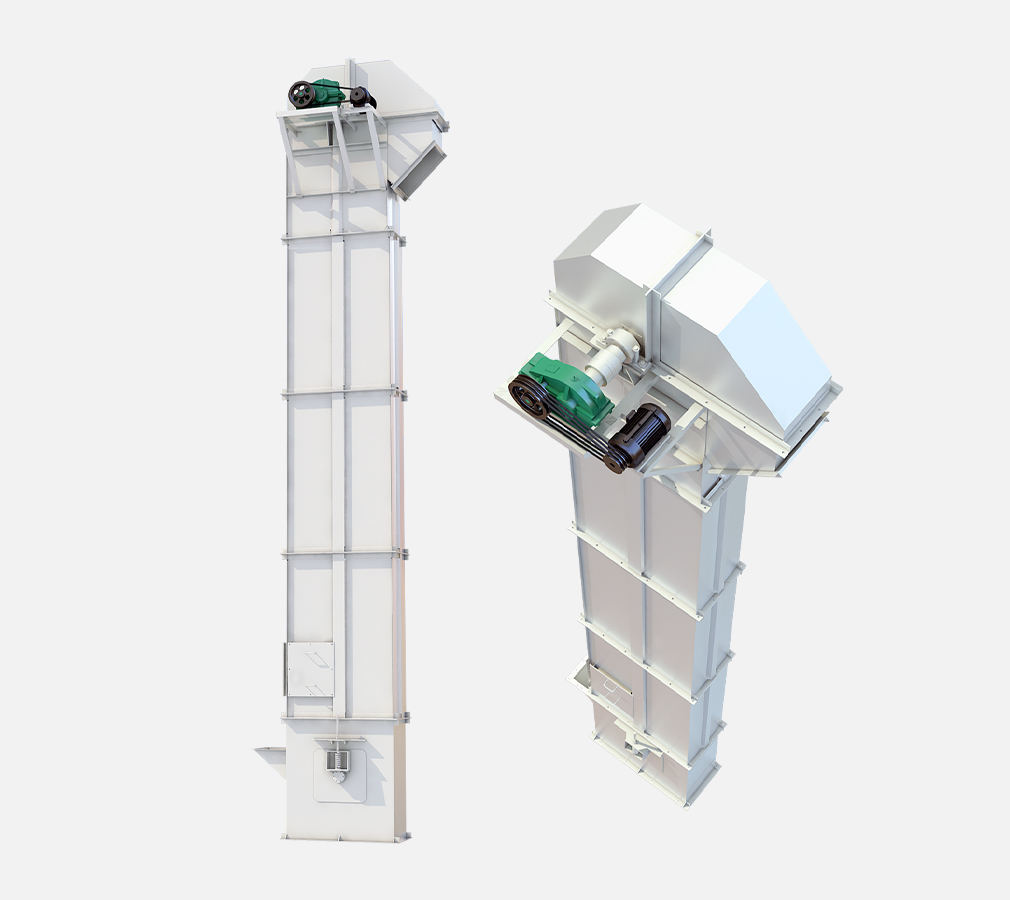

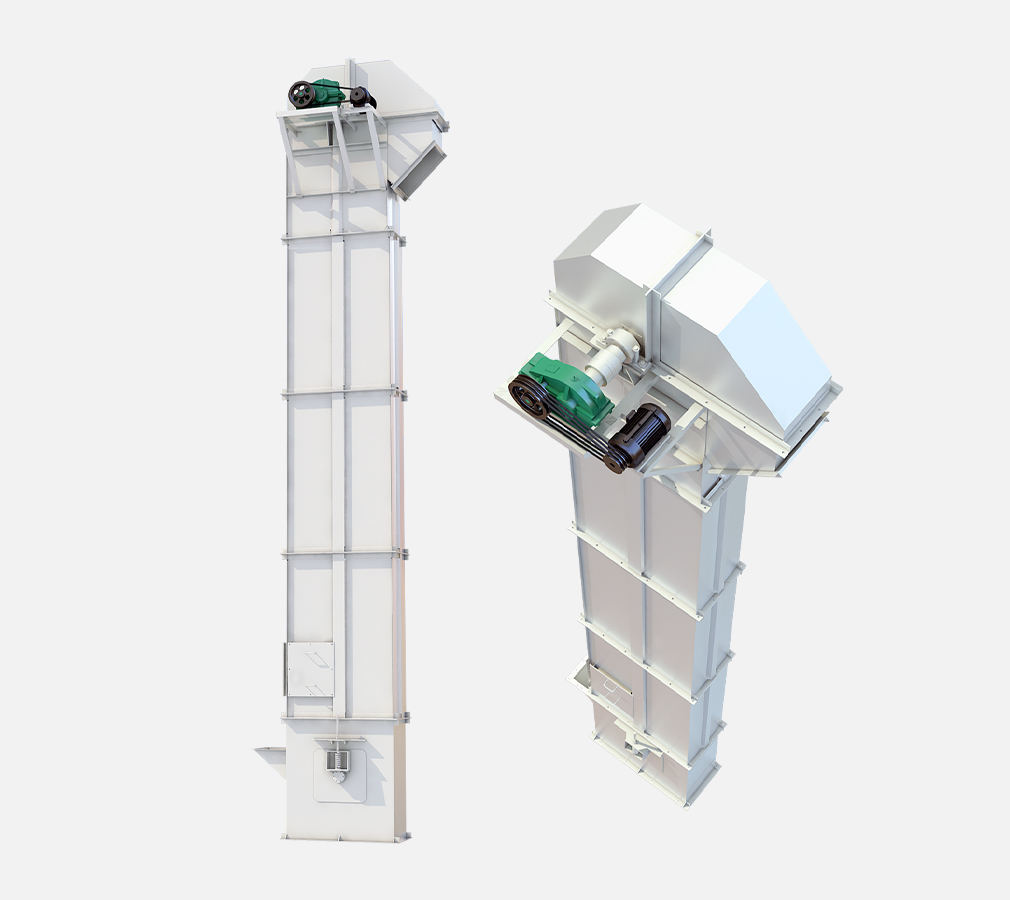

Our lifting equipment includes three types: chain type, plate chain type, and steel wire belt type. They all have the advantages of simple structure, large conveying capacity, high lifting height, and smooth operation.

Get the Latest PriceBucket elevators are mainly suitable for dry bulk materials with a density lower than 1.6 and a temperature lower than 250°C, such as coal, fly ash, cement, limestone, sand, clay, ore, slag, compound fertilizer, etc.

Technical parameters of ring chain bucket elevator

| Specification | Max.lifting Height (m) |

Conveying Capacity (m³/h) |

Max.size (mm) |

Pitch of Buckets (mm) |

Motor Prower (kw) |

| TH160 | 25 | 7-12 | 15-20 | 400 | 3-4 |

| TH200 | 28 | 8-15 | 20-30 | 500 | 3-5.5 |

| TH250 | 30 | 10-25 | 25-35 | 500 | 4-7.5 |

| TH300 | 30 | 25-35 | 30-40 | 500 | 5.5-11 |

| TH315 | 40 | 30-40 | 35-45 | 512 | 5.5-15 |

| TH400 | 40 | 45-60 | 40-55 | 512 | 11-22 |

| TH500 | 40 | 65-80 | 50-60 | 512 | 15-30 |

| TH630 | 40 | 100-120 | 60-65 | 688 | 18.5-37 |

| TH800 | 40 | 130-150 | 65-75 | 920 | 22-45 |

Technical parameters of wire belt bucket elevator

| Specification | Max.lifting Height (m) |

Conveying Capacity (m³/h) |

Max.size (mm) |

Bucket Volume (L) |

Motor Power (kw) |

| TDG160 | 80 | 34 | 0-20 | 2.6 | 2.2-11 |

| TDG200 | 80 | 45 | 0-25 | 4.1 | 3-15 |

| TDG250 | 80 | 71 | 0-30 | 6.5 | 5.5-22 |

| TDG315 | 80 | 101 | 0-35 | 10 | 7.5-30 |

| TDG400 | 80 | 158 | 0-40 | 16 | 15-45 |

| TDG500 | 80 | 218 | 0-45 | 25 | 18.5-55 |

| TDG630 | 80 | 345 | 0-50 | 40 | 30-90 |

| TDG800 | 80 | 491 | 0-50 | 61 | 45-132 |

Plate chain bucket elevator

| Specification | Max.lifting Height (m) |

Max.lifting Capacity (m³/h) |

Percentage Allowed(%) |

Pitch (mm) |

Motor Power (kw) |

||||

| 10 | 25 | 50 | 75 | 100 | |||||

| Max.size(mm) | |||||||||

| NE15 | 40 | 16 | 65 | 50 | 40 | 30 | 25 | 101.66 | 1.5-4 |

| NE30 | 59 | 31 | 90 | 75 | 58 | 47 | 40 | 152.4 | 2.2-7.5 |

| NE50 | 62 | 60 | 90 | 75 | 58 | 47 | 40 | 152.4 | 3-15 |

| NE100 | 58 | 110 | 130 | 105 | 80 | 65 | 55 | 200 | 7.5-30 |

| NE150 | 65 | 170 | 130 | 105 | 80 | 65 | 55 | 200 | 11-37 |

| NE200 | 73 | 220 | 170 | 135 | 100 | 85 | 70 | 250 | 18.5-75 |

| NE300 | 61 | 320 | 170 | 135 | 100 | 85 | 70 | 250 | 22-75 |

| NE400 | 47 | 420 | 205 | 165 | 125 | 105 | 90 | 300 | 45-90 |

| NE500 | 58 | 500 | 240 | 190 | 145 | 120 | 100 | 300 | 45-132 |

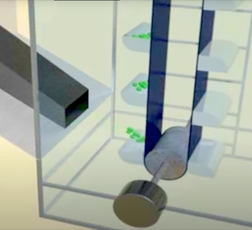

A functional elevator retrieves material from storage below using a hopper. A conveyor belt or chain lifts the material to the top, where it is poured into a receiving tank when the bucket flips downward. Belt-driven elevators utilize rubber belts on rollers, while chain-driven ones use parallel chains and sprockets. The elevator is enclosed with an organic shell to contain dust.

It features a compact design for easy operation and minimal maintenance requirements.

It is capable of handling a wide range of materials, including highly abrasive powders, with high lifting height and large conveying capacity.

It utilizes inflow feed to minimize material backflow and wear, along with a welded casing for increased rigidity and reliability. Equipped with a reliable backstop to prevent accidents during sudden load shutdown.

It offers multiple discharging methods such as mixing, gravity, and centrifugal, with a gravity-induced discharge option for low energy consumption. Ensures strong sealing for dust-free operation.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.