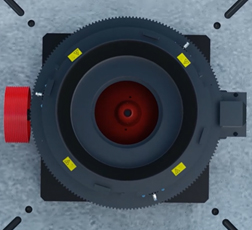

In order to crush hard rocks easily and produce finished products with good particle shape, we have developed hydraulic cone crushers that are widely used in medium crushing, fine crushing and ultra-fine crushing processes. It can be divided into three types: single cylinder hydraulic cone crusher, multi-cylinder hydraulic cone crusher and fully hydraulic cone crusher.

Hydraulic cone crushers are widely used in mining, cement plants and sand making industries. They are generally used as medium and fine crushers, and together with primary crushers (such as jaw crushers or gyratory crushers) form a complete crushing system.

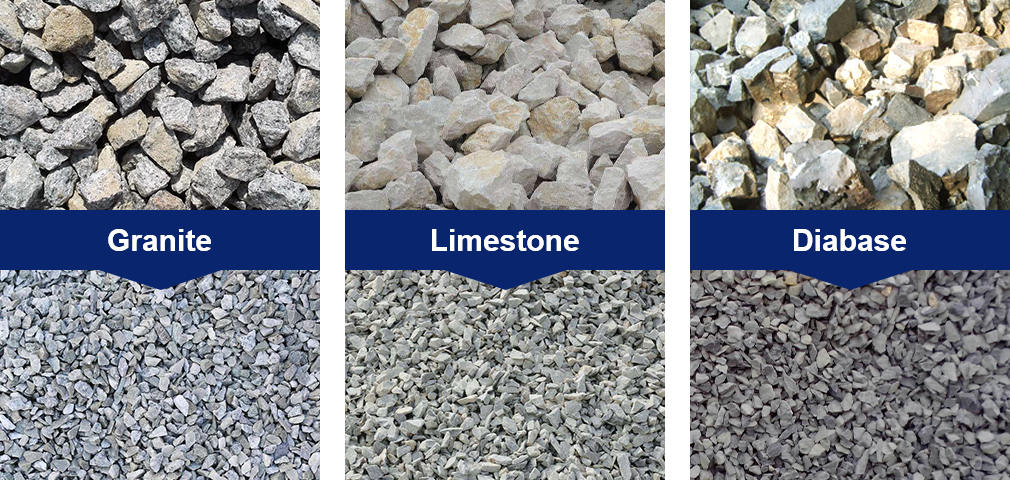

Get the Latest PriceThe cone crusher is particularly suitable for crushing hard rock, that is, crushing materials below 350 MPa, such as basalt, granite, non-ferrous metal ores, concrete, construction waste, etc.

| Model | Cavities | Broken cone big end diameter(mm) | Feeding Size(mm) | Max.feeding Size(mm) | Adjusting Range of Discharge Opening(mm) | Processing capacity(t/h) | Power(kw) | Weight of main machine(t) |

| GYS 300 | C1 | 910 | 175 | 140 | 13-38 | 81-180 | 90 | 10 |

| C2 | 102 | 80 | 9-22 | 60-180 | ||||

| F1 | 76 | 60 | 3-16 | 36-145 | ||||

| F2 | 41 | 30 | 3-13 | 36-130 | ||||

| GYS 400 | C1 | 1200 | 241 | 190 | 19-51 | 207-400 | 200 | 20 |

| C2 | 210 | 168 | 16-38 | 162-350 | ||||

| C3 | 137 | 110 | 13-31 | 126-310 | ||||

| F1 | 105 | 85 | 8-25 | 109-230 | ||||

| F2 | 89 | 70 | 6-16 | 82-230 | ||||

| F3 | 64 | 50 | 3-16 | 40-230 | ||||

| GYS 500 | C1 | 1600 | 269 | 215 | 25-64 | 280-650 | 280 | 40 |

| C2 | 241 | 190 | 22-51 | 258-450 | ||||

| C3 | 209 | 170 | 16-38 | 180-410 | ||||

| F1 | 133 | 105 | 10-25 | 162-355 | ||||

| F2 | 89 | 70 | 6-19 | 136-330 | ||||

| F3 | 70 | 55 | 5-13 | 90-300 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

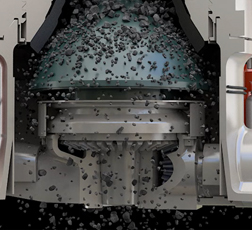

While in operation, the electric motor propels the transmission shaft via a pulley or coupling mechanism. This induces periodic rotational and oscillating movements in the moving cone, driven by the eccentric sleeve's force. Within the crushing cavity, the raw materials undergo compression, impact, and eventual fragmentation.

Achieve high crushing ratios and exceptional production capacity, surpassing conventional cone crushers.

Tailor your output to diverse particle sizes with ease, offering standard, medium, and short head chamber options for medium, fine, and ultra-fine crushing requirements.

Benefit from high manganese steel wearing parts and extended equipment lifespan with long-lasting liners. Experience simplified maintenance, low operating costs, and straightforward structure.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.