The agitation leaching tank is widely used to mix materials before flotation, making it popular in industries like chemicals, construction, cyanide plants, wastewater treatment, and coal preparation.

The mixing tank can stir the minerals before the flotation process, so that the slurry and chemicals are fully mixed evenly, increasing the reaction time, enhancing the quality of the drug reaction, and creating conditions for flotation treatment. It is also suitable for mixing various non-metallic ores.

Get the Latest PriceThe agitation tank is designed for substances with concentrations below 30% and particle sizes under 1 mm. Examples of suitable materials include quartz, plastic powder, carbon black, hematite, limonite, molybdenum ore, gold ore, iron ore, and more.

| Model | S112 | S114 |

| Design volume(m³/time) | 0.2 | 0.43 |

| Stir time(min) | 3-8 | 2-3 |

| Capacity(t/h) | 3-5 | 10-13 |

| Motor power(kw) | 7.5 | 15 |

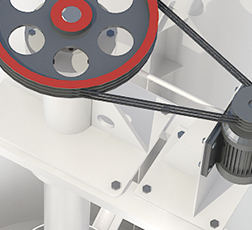

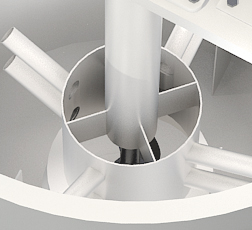

As the machine operates, the pulp and chemicals undergo a circular motion propelled by the impeller's rotation, ensuring thorough mixing throughout the tank. The blended suspension is then discharged from the overflow section.

Multiple rows of nozzles are utilized to ensure consistent water flow across the area, promoting uniformity in distribution.

Utilization of a fan-shaped propeller facilitates thorough mixing, maximizing contact between water and additives for optimal results.

The system is designed to maintain stable production quality, with quick discharge capabilities enhancing efficiency.

A reliable sealing mechanism and dust-proof board at the discharging port prevent contamination by water and floc, ensuring product integrity.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.