In crushing and sand making production lines, we often use the compound crusher (vertical compound crusher). It is a dual-rotor primary impact crusher without screen bars.

The compound crusher has a high sand production rate, so it is also a commonly used sand making equipment. 80% of 0-5 mm sand can be produced directly. If the sand making requirements are strict, a vibrating screen can be added.

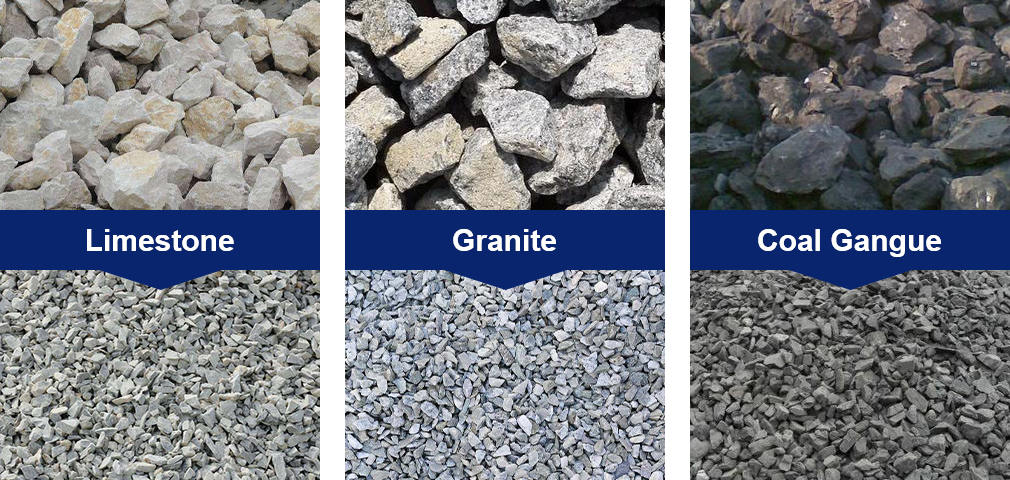

Get the Latest PriceComposite crushers are used for materials with medium hardness and below, compressive strength not exceeding 140 MPa, and humidity not exceeding 15%, such as coal gangue, granite, limestone, cement clinker, etc.

| Specification | Capacity(t/h) | Power(kw) |

| 800 | 5-15 | 4P 30 |

| 1000 | 10-30 | 4P 55 |

| 1250 | 17-60 | 6P 132 |

| 1500 | 25-80 | 8P 160 |

| 1750 | 30-100 | 8P 200 |

Composite crushing operates on the stone-on-stone principle. The motor drives the rotor, which spins the hammer at high speed. Material enters through the feed port, is struck by the hammer, and crushed against the inner wall until it exits through the lower discharge port.

The crusher has a screenless structure to prevent clogging, especially for high-moisture materials.

Long-life bearings arranged horizontally for crushing high-temperature materials like cement clinker, with a rotor made of solid cast steel for increased capacity.

Adjustable output size through the gap between hammers and impact plate, ensuring uniform particle size and low over-crushing rate, with hammers made of high-toughness multi-alloy material for increased crushing strength.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.