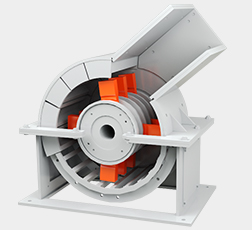

Our hammer mill crusher is commonly known as the PC series. Its simple structure and unique rotary hammer make it easy to operate, handling crushing and forming tasks in a single operation.

Hammer crusher is a commonly used medium and fine crusher. It can simplify the crushing process, directly crush large pieces of raw ore, and achieve medium and fine crushing effects on materials at one time.

Get the Latest PriceHammer crushers can crush medium-hard and brittle materials with humidity not exceeding 15%, such as coal rock, coal gangue, glass, concrete, road rocks, limestone, etc.

| Specification | Capacity(t/h) | Power (kw) |

| PC 400×300 | 3-10 | 4P 11 |

| PC 600×400 | 6-22 | 4P 22 |

| PC 800×600 | 10-40 | 4P 55 |

| PC 1000×800 | 15-50 | 4P 75 |

| PC 1000×1000 | 18-75 | 4P 90 |

| PC 1200×1200 | 22-95 | 4P 132 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Hammer mills crush materials using rotating hammers powered by a motor, propelling them towards an impact plate. Material is repeatedly hammered until desired size, then discharged through a bottom screen plate. Gap between impact plate and rotor can be adjusted for specific requirements.

The crusher boasts large feed particle size and a significant crushing ratio ranging from 10 to 50, leading to high output capacity.

It simplifies crushing operations by completing coarse and medium crushing in a single step, enhancing efficiency and reducing complexity.

Utilizes high-chromium iron hammer for prolonged service life, along with a thoughtfully designed bearing seat and automatic lubrication system, ensuring uninterrupted operation and minimal maintenance requirements.

Provides small, uniform, cubic discharging granularity with minimal over-crushing, adjustable particle sizes (coarse, medium, and fine), and low maintenance costs, power consumption, and energy consumption. Additionally, it offers excellent sealing properties and is competitively priced, being 10% lower than market rates.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.