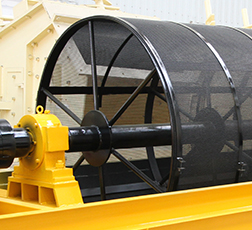

The drum screen is a new type of screening equipment that separates materials according to particle size. It has a simple structure, high screening efficiency and large output, and is very suitable for screening dust particles and sticky materials.

The trommel screen is an efficient and durable screening equipment. It is more suitable than the vibrating screen for screening materials and dust with high moisture content.

During the screening process, the material is not easy to block the screen, and the processing capacity is large.

Get the Latest PriceThe trommel screen is mainly suitable for coal, coal gangue, fly ash, granite, cobblestone, quartz sand, white ash, slag, compound fertilizer, compost, municipal solid waste, gravel aggregate, and other materials.

| Model | Capacity (t/h) | Power (kw) |

|

| Sieve hole(2mm) | Sieve hole(30mm) | ||

| YTS1230 | 4-12 | 16-50 | 5.5 |

| YTS1240 | 4.5-14 | 20-60 | 5.5 |

| YTS1250 | 5-15 | 23-70 | 5.5 |

| YTS1530 | 6-18 | 25-75 | 5.5 |

| YTS1540 | 6-18 | 25-75 | 7.5 |

| YTS1550 | 7-20 | 26-80 | 11 |

| YTS1560 | 7-22 | 33-100 | 11 |

| YTS2040 | 8-25 | 40-120 | 11 |

| YTS2050 | 10-30 | 50-150 | 11 |

| YTS2060 | 12-35 | 55-175 | 11 |

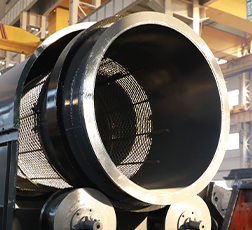

The motor is in contact with the drum through the coupling through the reduction gear. The drum rotates driven by the motor, and the material is fed into the drum. Qualified materials pass downward through the opening of the screen, and unqualified materials are discharged at the end.

Featuring a sandblasting cleaning mechanism and a comb screen structure, this screen machine efficiently sifts and purifies delicate and adhesive materials like topsoil and quartz sand, preventing screen blockages.

This unit features a low-energy motor for powerful processing, cutting operational time in half compared to other screens. It operates quietly and includes a sealed cover to prevent dust dispersion, enhancing efficiency and saving energy.

Rugged construction ensures durability, and special screens increase efficiency and extend screen life. Overall, it offers high reliability and low initial investment.

Simple box frame construction requires only a flat surface for installation, removal or maintenance.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.