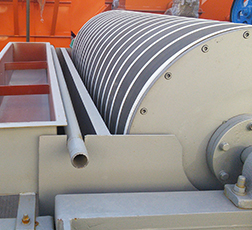

A magnetic separator is a piece of equipment utilized in mineral processing, employing both magnetic and mechanical forces to segregate magnetic materials within a mixture.

According to different operating modes, magnetic separators can be divided into dry magnetic separators and wet magnetic separators. The wet permanent magnet cylinder magnetic separator is suitable for strong magnetic minerals. It has also been used as a concentration equipment to replace the magnetic dewatering tank before filtration.

Get the Latest PriceMagnetic separator is suitable for sorting metal ores below 3 mm, such as hematite, limonite, manganese ore, etc.

It is also used for removing iron from various materials like quartz, feldspar, rutile, garnet, coal, ceramics, glass, wastewater, sludge, foundry sand, and more.

| Model |

Shell diameter (mm) |

Shell lenght (mm) |

Shell rotation speed(r/min) |

Feeding size (mm) |

Processing capacoty (t/h) |

Power(kw) |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

| CTB1530 | 1500 | 3000 | <14 | 3-0 | 170-280 | 11 |

The magnetic separator uses the power of a water pump to introduce water into the mining area through the ore box. Magnetism then promotes adhesion, causing non-magnetic or minimally magnetic minerals to be expelled from the reservoir.

Utilizes permanent magnets composed of ferrite or a composite of ferrite material and rare earth magnetic steel. This design creates a strong and enduring magnetic field with a short magnetic circuit, reducing magnetic flux leakage.

Offers adjustable magnetic intensity ranging from 1000 to 5000 Gauss on average, extendable to 8000 mT, which currently stands as the world's highest magnetic field intensity. This feature enhances versatility in various applications.

Implements a dynamic magnetic system that prevents material adhesion to the roller, facilitating effective material sorting processes and enhancing operational efficiency.

The drum, tank body, and frame are constructed using high-quality stainless steel plates, preventing magnet peeling and ensuring durability under demanding conditions.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.