The rod mill is ideal for coarse grinding of brittle materials with low hardness or as the first stage of two-stage ball mill grinding. It ensures efficient grinding without excessive crushing. Recently, it has become popular in construction sand making.

The rod mill uses steel rods for dry or wet grinding. The particle size of the output material is fine and uniform, which can prevent over-grinding, but is coarser than the ball mill.

Get the Latest PriceThe rod mill can grind these materials: rare metal ores (tungsten, tin), gold, iron, copper, quartzite, potassium feldspar, gravel, coal, glass, construction waste, cement clinker, fertilizer, etc.

| Model |

Shell Specifications (mm)

|

Shell rotation speed (r/min) |

Feeding size (mm) |

Discharging size (mm) |

Processing capacity (t/h) |

Power (kw) |

Total weight (t) |

|

| Diameter | Length | |||||||

| MBS0918 | 900 | 1800 | 36-38 | ≤25 | 0.833-0.147 | 0.62-3.2 | 18.5 | 5.9 |

| MBS0924 | 900 | 2400 | 36 | ≤25 | 0.833-0.147 | 0.81-4.3 | 22 | 6.7 |

| MBS1224 | 1200 | 2400 | 36 | ≤25 | 0.833-0.147 | 1.1-4.9 | 30 | 13.9 |

| MBS1530 | 1500 | 3000 | 29.7 | ≤25 | 0.833-0.147 | 2.4-7.5 | 75 | 19.8 |

| MBS1830 | 1830 | 3000 | 25.4 | ≤25 | 0.833-0.147 | 4.8-11.6 | 130 | 34.9 |

| MBS2130 | 2100 | 3000 | 23.7 | ≤25 | 0.833-0.147 | 14-35 | 155 | 46.5 |

| MBS2136 | 2100 | 3600 | 23.7 | ≤25 | 0.833-0.147 | 19-43 | 180 | 48.7 |

| MBS2430 | 2400 | 3000 | 21 | ≤50 | 0.833-0.147 | 25-65 | 245 | 59.7 |

| MBS2736 | 2700 | 3600 | 20.7 | ≤50 | 0.833-0.147 | 32-86 | 380 | 92.5 |

| MBS2740 | 2700 | 4000 | 20.7 | ≤50 | 0.833-0.147 | 32-92 | 400 | 95 |

| MBS3245 | 3200 | 4500 | 18 | ≤50 | 0.833-0.147 | 64-180 | 630 | 149 |

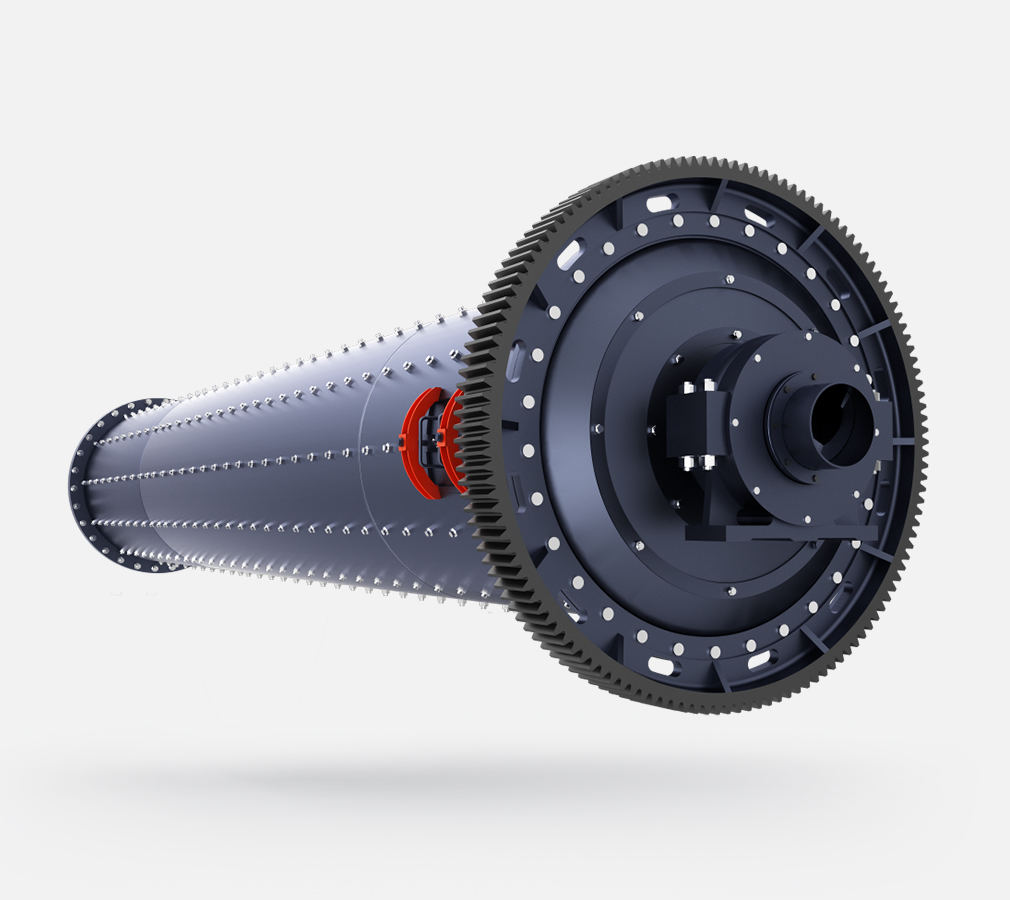

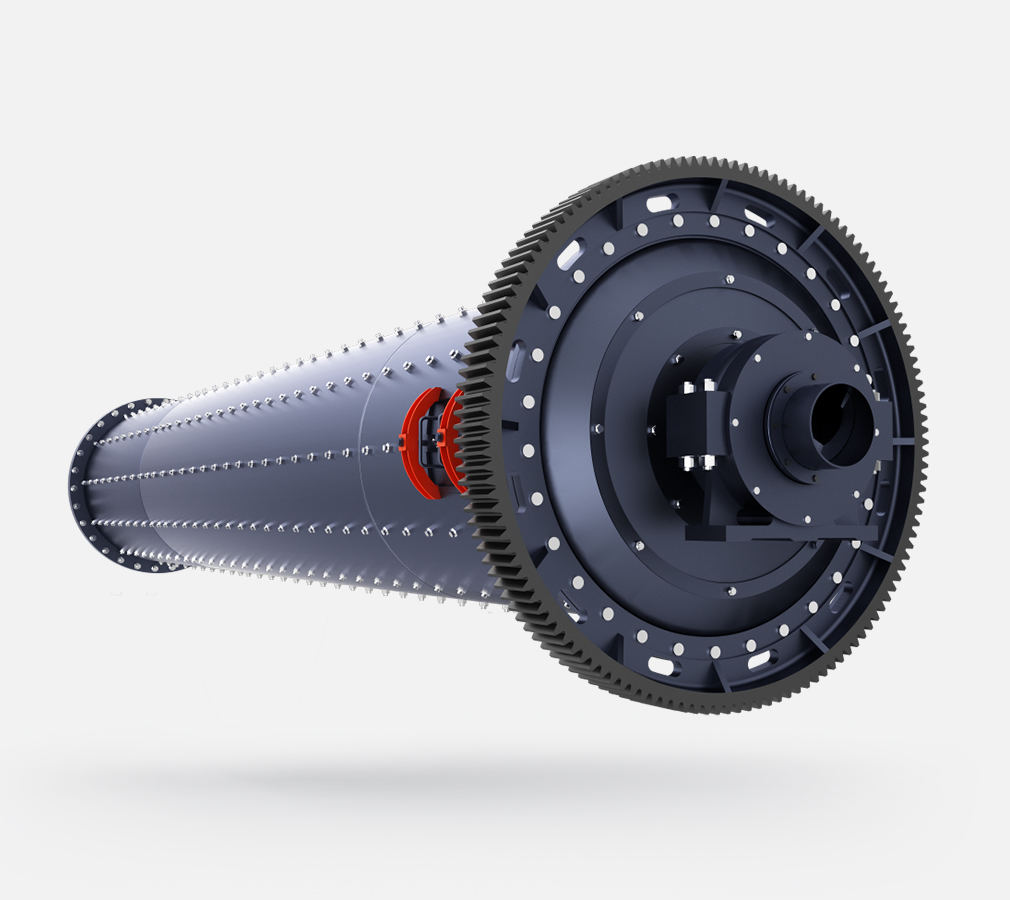

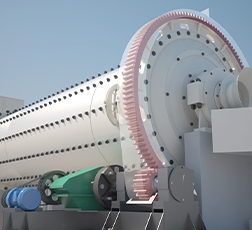

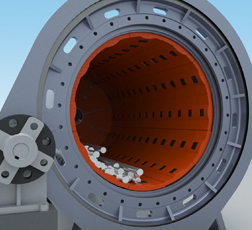

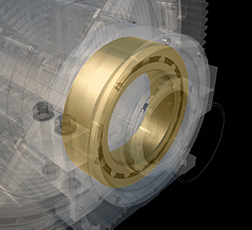

A rod mill, driven by external gear, features a horizontal rotary cylinder. Material enters the first cabin with liner plates and steel rods. The rotating cylinder elevates and drops rods to grind the material. Coarse material moves to the second cabin for further grinding. Finally, powdery material exits from the discharge port, completing the process.

Rod mills offer a significant advantage with a large crushing ratio, resulting in a fine and uniform output particle size, albeit coarser than that achieved by a ball mill.

The steel rod grinding mechanism of rod mills ensures less over-crushing, breaking ore into coarse particles before further size reduction, leading to more efficient processing.

These rod mills deliver a high proportion of medium sand with good gradation continuity during the sand making process, meeting the production needs of various grinding mills and sand making plants, regardless of size.

These rod mills ensure efficient, low-maintenance operation, saving power and enhancing capacity.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.