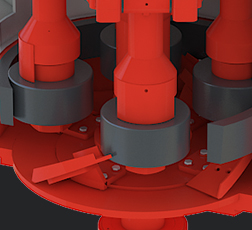

The Raymond mill exhibits versatility as a fine powder mill, integrating grinding, classification, and drying operations. Its mechanism involves utilizing a scraper to transfer material between the grinding rollers and rings, producing fine powder.

Raymond mill is very popular in the powder market due to its low price, high grinding efficiency and durability of the machine. If you have limited budget and plan to produce high-quality fine powder, Raymond mill is a reliable choice for you.

Get the Latest PriceRaymond mills can process a variety of materials including non-metallic minerals such as limestone, quartz, feldspar, gypsum, graphite, and dolomite, as well as coal, glass, cement clinker, and other substances.

| Model | 4525 | 4119 |

| Feeding Size(mm) | ≤30 | ≤25 |

| Output Size(mm) | 0.173-0.044 | 0.173-0.044 |

| Shift Output of Different Material Fineness(t) | 16-176 | 8-78 |

| Rotation Speed of Central Shaft(r/min) | 82 | 105 |

| Ring Diameter(mm) | 1770 | 1400 |

| Roller Diameter(mm) | 450 | 410 |

| Roller Height(mm) | 250 | 190 |

| Main Motor(kw) | Y315M-4-132 | Y280S-4-75 |

| Fan Motor | Y315M-4-132 | Y280S-4-75 |

| Analyzer Motor | YCT250-4A-18.5 | YCT200-4B-7.5 |

Raymond roller mill, combined with bucket elevator and dust collector, efficiently produces clean powder:

1. Material crushed by crusher.

2. Sent to hopper via elevator, then fed to mill for grinding by vibrating feeder.

3. Powder sorted by air separator using circulating air from blower. Coarse material re-ground. Qualified powder enters cyclone collector and discharged.

4. Dust collector controls emissions and prevents mill clogging by promptly removing excess dust.

Raymond mills optimize grinding force with a spring-assisted mechanism for enhanced performance.

Achieve high fineness levels and uniform output with over 99% sieving rate for consistent quality.

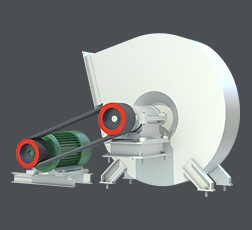

Sealed gearboxes and pulleys ensure smooth transmission, boosting efficiency and longevity.

Raymond mills boast durable components like high manganese scrapers and steel rollers, reducing maintenance. Efficient air separation minimizes dust and noise, with low investment requirements for accessibility.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.