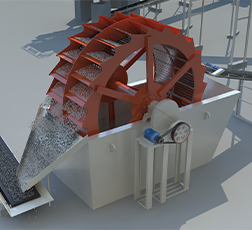

The wheel-type sand washer aims to improve the sand quality by washing away the impurities such as stone powder and soil. It offers versatility, operating either autonomously or in conjunction with a sand making machine.

The wheel sand washer works with the sand making machine to produce artificial sand. Its sealed structure, enclosed transmission, and adjustable overflow weir ensure efficiency, durability, and stability, especially for fine-grained products. When dealing with muddy sand, employing two washers ensures the cleanest results.

Get the Latest PriceSand and gravel with large mud content, such as river pebbles, granite, basalt, barite, shale, marble, talc, calcite, dolomite, fluorite, kaolin, coal and gypsum, etc.

| Specification | Processing Capacity (t/h) |

Motor Power (kw) |

| XS2308 | 15-40 | 4 |

| XS2711 | 20-65 | 5.5 |

| XS3014 | 50-100 | 7.5 |

| XS3220 | 80-200 | 11 |

| XS3227 | 100-260 | 15 |

| XS4215 | 200-300 | 15 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

The power unit spins the impeller, which churns sand and gravel in the washing tank, purifying them as water is added for a strong flow. Clean material goes to the discharging trough, while impurities are expelled from the overflow washing trough, finishing the cleaning process.

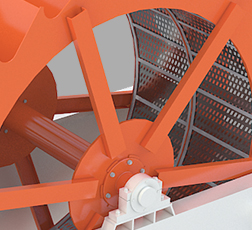

It has a simple structure, a small footprint, and no other wearing parts except the screen.

The washing efficiency is high and meets the requirements of high-end materials. And there is less loss of fine sand.

The screen is installed on the blade with bolts, the discharge granularity is adjustable, and maintenance and replacement are easy.

Low water consumption, saving water resources. The transmission device is isolated from sand and water to avoid pollution and rust, so the failure rate is low.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.