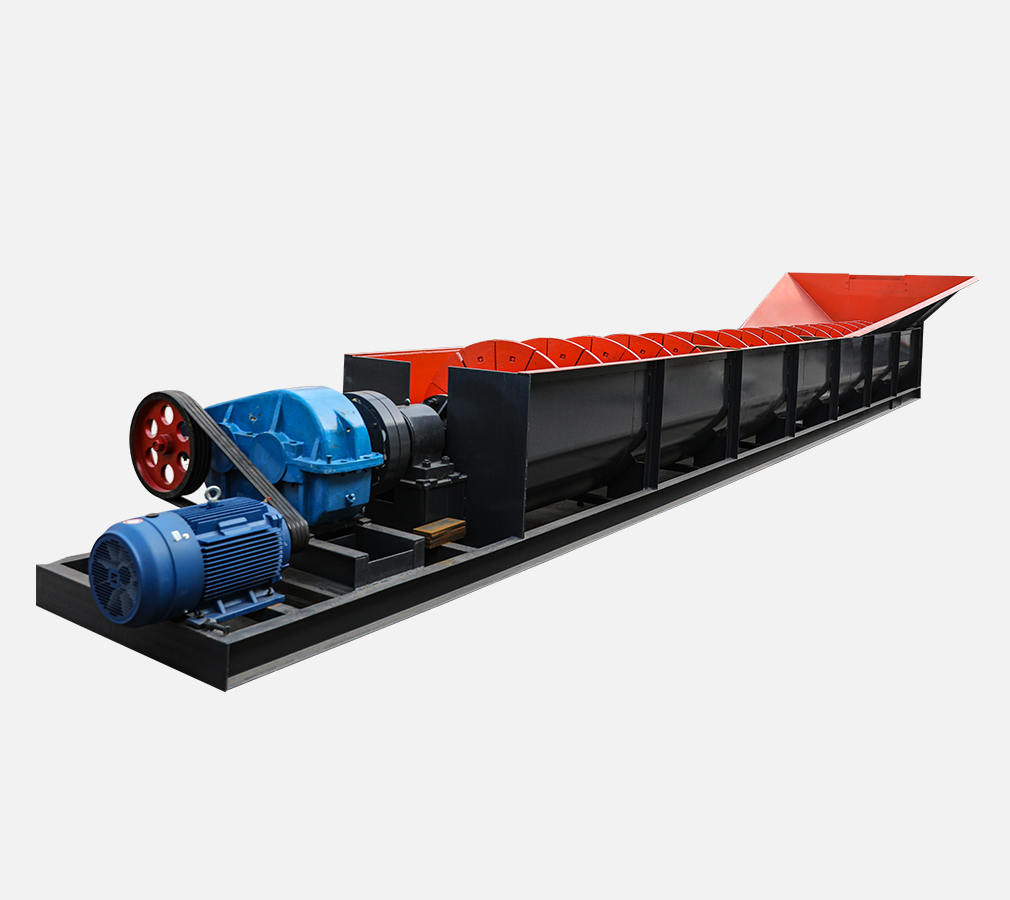

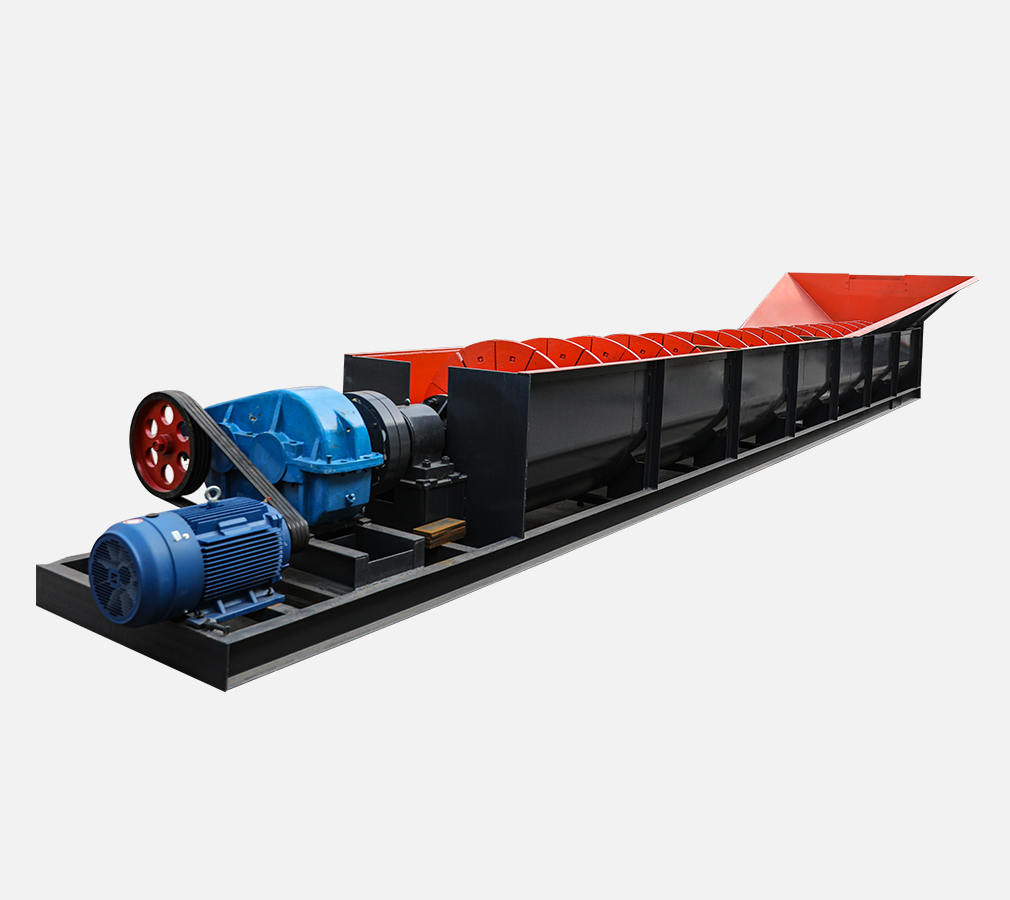

The spiral sand washing machine is a horizontal structure sand washing equipment and an upgraded version of the wheel sand washing machine. It uses an internal spiral device to produce high-quality sand through optimal cleaning, screening and dehydration.

According to the number of spirals, the spiral sand washer can be divided into the single spiral washer and double spiral washer. The double screw sand washer has a greater output and higher efficiency, and can wash materials with high mud content.

Get the Latest PriceRiver pebble, granite, basalt, barite, shale, marble, talc, calcite, dolomite, fluorite, kaolin, coal, gypsum, etc.

| Model | Screw diameter (mm) |

the sink length (mm) |

screen plate size (mm) |

Feeding size (mm) |

Sand production (t/h) |

standard segregator specification |

standard total power (kw) |

| LX765-15-55 | 765 | 6500 | 1500x3000 | ≤10 | 20-60 | 2x250 | 39 |

| LX915-15-65 | 915 | 7650 | 1500x3000 | ≤10 | 30-100 | 2x300 | 47 |

| 2LX915-24-100 | 915 | 7650 | 2400x4500 | ≤10 | 60-200 | 4x250 | 81 |

| LX1115-18-75 | 1115 | 8650 | 1800x4500 | ≤10 | 40-120 | 2x350 | 60 |

| 2LX1115-30-120 | 1115 | 8650 | 3000x4800 | ≤10 | 80-240 | 4x300 | 120 |

The spiral sand washing machine uses the spiral principle and the difference in the settling speed of various materials in the liquid to wash sand. The transmission part drives the spiral shaft to rotate continuously to mix and classify the materials. Low specific gravity impurities are discharged from the overflow bin, while clean sand is discharged from the outlet.

It can handle sand and gravel containing heavy clay and dust for higher cleanliness. The moisture content of washed sand is as low as 0.8%, which meets the requirements of high-end sand.

It has high processing capacity and high washing efficiency, and is often deployed in large sand making plants.

There is no need for a screen, and the entire machine is made of wear-resistant special materials to avoid the problem of water freezing in winter.

The operation is simple, the degree of automation is high, the energy consumption is low, and the purified sewage can be recycled through the sedimentation tank.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.